High-Quality Diamond Holder Tool for Precision Cutting

By:Admin

From its inception, the Diamond Holder Tool has revolutionized the way diamond tools are used and has set a new standard for performance and efficiency. The company behind this groundbreaking invention, {Company Name}, has dedicated itself to creating top-of-the-line products that meet the ever-evolving needs of its customers. With a mission to deliver excellence and innovation, {Company Name} has made a significant impact on the industry, and its Diamond Holder Tool is a testament to its commitment to quality and reliability.

The Diamond Holder Tool has been designed with the user in mind, featuring a robust construction and ergonomic design that ensures ease of use and maximum effectiveness. With its precision-engineered components and durable materials, this tool offers unparalleled stability and support, allowing diamond tools to perform at their best without any compromises. Whether it's for cutting, drilling, or grinding, the Diamond Holder Tool provides a secure and dependable solution that professionals can rely on for their most demanding tasks.

One of the key benefits of the Diamond Holder Tool is its versatility, as it can accommodate a wide range of diamond tools, including blades, core bits, and cup wheels. This flexibility makes it an ideal choice for various applications, whether it's in construction, masonry, or stone fabrication. The tool's adjustable features also allow for easy customization, ensuring a perfect fit for different size tools and providing users with the adaptability they need to tackle different projects with confidence.

In addition to its exceptional performance, the Diamond Holder Tool is also designed for long-term durability, with high-quality materials and precision engineering that prolong its lifespan and maintain its effectiveness over time. This reliability not only brings peace of mind to users but also contributes to cost savings by reducing the need for frequent replacements or repairs. With the Diamond Holder Tool, professionals can count on a consistent and dependable solution that delivers results day in and day out.

Furthermore, {Company Name} is committed to providing top-notch customer support and service, ensuring that every customer receives the assistance they need and the attention they deserve. The company's team of experts is dedicated to helping clients find the right solutions for their specific requirements and is always available to address any questions or concerns. This commitment to customer satisfaction has made {Company Name} a trusted partner for many professionals in the industry, further solidifying its reputation as a leader in the market.

Looking ahead, {Company Name} continues to innovate and develop new technologies that push the boundaries of what's possible in the diamond cutting and drilling industry. With a strong focus on research and development, the company is constantly seeking ways to enhance its products and create even more efficient and effective solutions for its customers. As a result, professionals can look forward to future advancements that will further elevate their performance and productivity.

In conclusion, the Diamond Holder Tool from {Company Name} has earned its place as a game-changer in the diamond cutting and drilling industry, offering unmatched performance, reliability, and versatility. Backed by a company that is dedicated to excellence and innovation, this innovative tool has become a go-to solution for professionals who demand the best. With its proven track record and commitment to customer satisfaction, {Company Name} continues to lead the way in providing cutting-edge solutions that empower professionals to achieve exceptional results in their work.

Company News & Blog

Durable and Efficient Cutting Tools for Diamond Processing

Diamond cutting tools are an essential component in a wide range of industries, including construction, automotive, aerospace, and mining. These tools are renowned for their strength, durability, and precision, making them an indispensable asset for companies in need of high-quality cutting solutions. One company that has been at the forefront of producing top-notch diamond cutting tools is (remove brand name). With a rich history dating back over 50 years, (remove brand name) has established itself as a leader in the manufacturing and distribution of diamond cutting tools. The company's commitment to innovation, quality, and customer satisfaction has earned them a strong reputation in the industry.One of the key factors that sets (remove brand name) apart from its competitors is its use of advanced technology and state-of-the-art machinery in the production process. The company's manufacturing facilities are equipped with the latest machinery and equipment, allowing for the precise and efficient production of diamond cutting tools. This commitment to technological advancement ensures that (remove brand name) remains at the forefront of the industry, constantly delivering cutting-edge solutions to its customers.In addition to its technological prowess, (remove brand name) is also known for its emphasis on research and development. The company boasts a team of highly skilled engineers and designers who are dedicated to creating innovative and efficient cutting tool solutions. Through extensive research and testing, (remove brand name) is able to develop cutting tools that are not only durable and reliable but also tailored to meet the specific needs of its customers.Furthermore, (remove brand name) takes great pride in its commitment to quality control and assurance. The company's rigorous quality control measures ensure that every single cutting tool produced meets the highest standards of performance and reliability. This dedication to quality has earned (remove brand name) the trust and loyalty of countless customers around the world.Another distinguishing factor of (remove brand name) is its dedication to customer service. The company's team of professionals is committed to providing unparalleled customer support, offering technical expertise, personalized solutions, and prompt assistance to ensure that every customer's needs are met. This customer-centric approach has been a driving force behind (remove brand name)'s success and has solidified its position as a trusted partner in the industry.Looking ahead, (remove brand name) is poised to continue its legacy of excellence in the production of diamond cutting tools. With a relentless focus on innovation, quality, and customer satisfaction, the company is well-equipped to meet the evolving needs of industries that rely on cutting-edge cutting solutions. (remove brand name) remains steadfast in its commitment to delivering top-quality products and services, ensuring that it will remain a leader in the diamond cutting tool industry for years to come.In conclusion, (remove brand name) is a company that exemplifies excellence in the production of diamond cutting tools. With its cutting-edge technology, commitment to research and development, emphasis on quality control, and dedication to customer service, (remove brand name) has earned a stellar reputation as a leader in the industry. As the company continues to innovate and expand its offerings, it is poised to remain a top choice for businesses in need of high-quality diamond cutting tools.

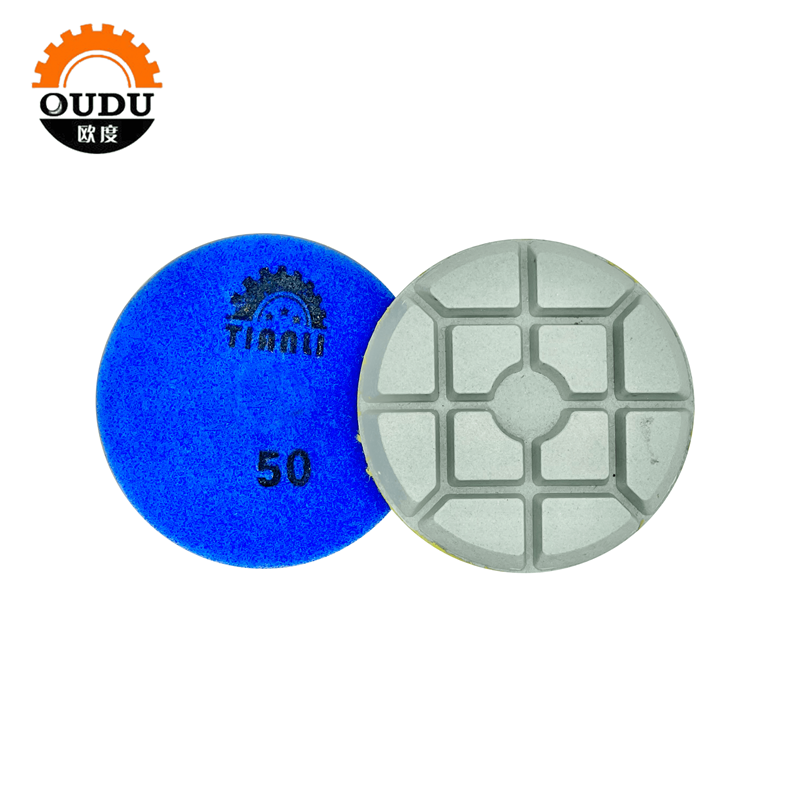

High-Quality Wet Polishing Pads for Granite: What You Need to Know

In the world of granite and stone fabrication, having the right tools and equipment is essential for achieving high-quality results. One of the most critical tools in this industry is wet polishing pads, which are used for grinding, honing, and polishing granite and other natural stones to achieve a smooth and glossy finish. One of the leading providers of wet polishing pads for granite is a company that has been at the forefront of the stone fabrication industry for over a decade. With a commitment to providing high-quality products and exceptional customer service, this company has become a trusted name among fabricators and contractors.The wet polishing pads offered by this company are designed to deliver outstanding performance and durability, allowing fabricators to achieve precise and consistent results with every use. These pads are engineered to minimize heat generation during the polishing process, reducing the risk of thermal shock to the stone and ensuring a superior finish.In addition to their exceptional performance, the wet polishing pads offered by this company are also designed for ease of use, featuring a quick and easy attachment system that allows for fast pad changes during the fabrication process. This not only improves efficiency but also reduces downtime, allowing fabricators to complete their projects in a timely manner.With a strong focus on innovation, this company is constantly working to improve and expand its product line to meet the evolving needs of the stone fabrication industry. They are committed to staying ahead of the curve and are always looking for ways to enhance the performance and durability of their wet polishing pads.To ensure the quality and reliability of their products, this company conducts rigorous testing and quality control measures at every stage of the manufacturing process. This dedication to quality has earned them a reputation for excellence within the industry, making them a go-to source for wet polishing pads for granite and other natural stones.Moreover, this company is dedicated to providing exceptional customer service, offering expert guidance and support to help fabricators choose the right tools and equipment for their specific needs. Their team of knowledgeable professionals is always available to answer questions and provide assistance, ensuring that their customers have a positive experience with every purchase.In addition to wet polishing pads, this company also offers a wide range of other essential tools and equipment for stone fabrication, including diamond blades, grinding wheels, and polishing compounds. Their comprehensive product line makes them a one-stop shop for fabricators looking to stock up on high-quality supplies for their projects.Overall, the wet polishing pads offered by this company are a testament to their commitment to quality, innovation, and customer satisfaction. With a focus on performance, durability, and ease of use, these pads are an essential tool for any fabricator looking to achieve professional results in granite and stone fabrication.As the stone fabrication industry continues to evolve, this company remains dedicated to staying at the forefront, offering cutting-edge products and exceptional service to meet the needs of fabricators and contractors. With a solid reputation for excellence and a track record of success, they are a trusted partner for professionals in the industry.

How to Choose the Best Polishing Pad: A Complete Guide

125 Polishing Pad, a leading company in the manufacturing of industrial polishing pads, has recently announced the launch of their latest product in the market. The company, with years of experience and expertise in the field, has built a reputation for delivering high-quality polishing pads that cater to the needs of various industries.Founded in [year], 125 Polishing Pad has always been committed to providing innovative and reliable solutions for polishing and finishing applications. The company's state-of-the-art manufacturing facility is equipped with the latest technology and machinery, allowing them to produce polishing pads that meet the highest standards of quality and performance.The newly launched polishing pad is a result of extensive research and development efforts by the company's team of experts. It is designed to offer superior performance and durability, making it an ideal choice for a wide range of industrial applications. The pad is made from high-quality materials that have been carefully selected to ensure optimal results during the polishing process.“We are thrilled to introduce our latest product to the market,” said [spokesperson's name], the CEO of 125 Polishing Pad. “We understand the importance of using the right tools and equipment for polishing and finishing tasks, and our new polishing pad has been engineered to deliver exceptional results. We believe that this product will set a new standard in the industry and provide our customers with a reliable solution for their polishing needs.”The 125 Polishing Pad is suitable for use on various surfaces, including metal, wood, plastic, and glass. It is available in different sizes and specifications to accommodate the diverse requirements of different applications. The pad is designed to be easy to use, providing consistent results with minimal effort.In addition to its superior performance, the polishing pad is also designed with durability in mind. It is engineered to withstand the rigors of industrial use, ensuring a long service life and cost-effective operation. This makes it an excellent investment for businesses looking to streamline their polishing and finishing processes.125 Polishing Pad is dedicated to providing exceptional customer service, and the launch of their new product is accompanied by a comprehensive support package. The company offers technical assistance, product training, and after-sales support to ensure that their customers get the most out of their investment. With their commitment to customer satisfaction, 125 Polishing Pad has established long-standing relationships with clients across various industries.The company’s dedication to quality and innovation has earned them a strong reputation in the industry, making them a trusted partner for businesses seeking reliable polishing solutions. Their products are widely used in manufacturing, automotive, aerospace, construction, and other sectors where precision finishing is essential. With the launch of the new polishing pad, 125 Polishing Pad is poised to further strengthen its position as a leader in the market.The new polishing pad is now available for purchase through the company's network of distributors and authorized retailers. With its exceptional performance, durability, and support services, the product is expected to make a significant impact in the industry and provide tangible benefits to businesses that rely on high-quality polishing solutions.In conclusion, the launch of the new polishing pad by 125 Polishing Pad represents a significant milestone for the company and the industry as a whole. With its advanced design, superior performance, and commitment to customer satisfaction, the product is set to become a preferred choice for businesses seeking reliable and efficient polishing solutions. As 125 Polishing Pad continues to push the boundaries of innovation, it is clear that they are poised to remain at the forefront of the industry for years to come.

Tips and Tricks for Polishing Marble Floors to Restore Their Shine

Title: Marble Polishing: Tips and Tricks to Restore the Shine of Your Marble FloorsIntroduction:Marble floors are renowned for their elegance and timeless beauty, but over time, they can lose their shine and develop scratches and stains. Using the right marble polishing techniques and tools can help you restore the natural luster of your marble floors. In this blog post, we will guide you through the process of polishing marble, using polishing powder and pads for both dry and wet polishing methods.Keywords: Marble Polishing, Polishing Powder, Polishing Pads, Marble Floors, Restore ShineI. Understanding Marble Polishing:- What is marble polishing?- The importance of regular marble floor maintenance.- Difference between dry and wet marble polishing techniques.- Benefits of using polishing powder and pads for marble restoration.- Marble polishing tools and equipment needed for the job.Keywords: Marble Polishing, Regular Maintenance, Dry Polishing, Wet Polishing, Polishing Powder, Polishing Pads, Marble Restoration, Tools and Equipment.II. Preparing Your Marble Floors for Polishing:- Inspecting and identifying any damages or stains.- Clearing the room and protecting surrounding surfaces.- Removing dust and debris from the marble surface.- Filling any cracks or holes in the marble.Keywords: Damages, Stains, Surface Preparation, Dust Removal, Crack Filling.III. Dry Marble Polishing Method: Steps and Procedures:- Choosing the right polishing powder for dry polishing.- Applying the polishing powder evenly on the marble surface.- Working the powder into the marble using a floor machine and a polishing pad.- Repeating the process until the desired shine is achieved.- Cleaning and buffing the marble surface after dry polishing.Keywords: Dry Polishing Method, Polishing Powder, Even Application, Floor Machine, Polishing Pad, Cleaning, Buffing.IV. Wet Marble Polishing Method: Steps and Procedures:- Preparing a mixture of water and polishing powder for wet polishing.- Applying the mixture onto the marble surface using a sprayer or a sponge.- Working the mixture into the marble with a floor machine and a polishing pad.- Rinsing off any excess powder and residues.- Drying and buffing the marble surface after wet polishing.Keywords: Wet Polishing Method, Water and Polishing Powder Mixture, Application, Sprayer, Sponge, Rinsing, Drying, Buffing.V. Additional Marble Polishing Tips and Tricks:- Regular cleaning and maintenance practices to prolong the shine.- Using pH-neutral cleaners for routine maintenance.- Avoiding abrasive materials or cleaners that may harm the marble surface.- Utilizing a protective sealant to enhance durability and resistance.- Seeking professional help for extensive damages or deep stains.Keywords: Cleaning and Maintenance, pH-Neutral Cleaners, Abrasive Materials, Protective Sealant, Professional Assistance.Conclusion:By following these marble polishing techniques and utilizing the appropriate tools, you can restore the natural shine and appeal of your marble floors. Whether you choose the dry or wet polishing method, remember to prioritize regular cleaning and maintenance to keep your marble floors looking their best.

Durable Aluminum Backer Pad for Polishing and Grinding applications

Aluminum Backer Pad is a leading manufacturer and supplier of top-quality diamond tools and accessories for the stone and construction industry. With a strong focus on innovation and quality, the company has established a solid reputation for providing professional-grade products that meet the needs of their customers.The company's Aluminum Backer Pad is a key component in the stone fabrication process, as it is designed to provide a stable and secure backing for diamond polishing pads. Made from high-quality aluminum, the backer pad is durable and long-lasting, ensuring that it can withstand the rigors of heavy-duty use. Its superior construction also allows for maximum flexibility and balance, making it ideal for polishing and grinding uneven surfaces.One of the key features of the Aluminum Backer Pad is its unique hook and loop design, which allows for quick and easy attachment and removal of diamond polishing pads. This innovative system makes it easy for fabricators to change out pads as needed, saving time and increasing efficiency in the work process. The backer pad's smooth and consistent performance also ensures a high-quality finish on the stone surface, delivering professional results with every use.In addition to its superior performance, the Aluminum Backer Pad is also designed with user comfort in mind. Its lightweight and ergonomic design minimizes operator fatigue, allowing for extended periods of use without strain or discomfort. This is particularly important in the stone fabrication industry, where precision and attention to detail are essential for achieving the desired finish on a wide range of materials.The company's commitment to quality and innovation is reflected in the Aluminum Backer Pad, which has quickly become a preferred choice among stone fabricators and construction professionals. Its reliability and durability make it a valuable asset in any tool collection, providing consistent performance and long-term cost savings for users.With a strong emphasis on customer satisfaction, Aluminum Backer Pad is dedicated to providing exceptional service and support to its clients. The company's team of knowledgeable and experienced professionals is always available to offer personalized guidance and assistance, ensuring that customers have access to the information and resources they need to get the most out of their products.In addition to its flagship Aluminum Backer Pad, the company offers a comprehensive range of diamond tools and accessories, including polishing pads, diamond blades, core bits, and more. Each product is carefully engineered to meet the highest standards of quality and performance, making Aluminum Backer Pad a trusted partner for professionals in the stone and construction industry.As the demand for high-quality diamond tools continues to grow, Aluminum Backer Pad remains at the forefront of the industry, constantly striving to develop new and innovative solutions that meet the evolving needs of its customers. With its unwavering commitment to excellence, the company is well-positioned to continue its success and maintain its status as a leading provider of diamond tools and accessories for years to come.In conclusion, Aluminum Backer Pad is a name synonymous with quality and reliability in the stone and construction industry. Its Aluminum Backer Pad is a testament to the company's commitment to innovation and excellence, providing professionals with a superior tool for achieving exceptional results. With a focus on customer satisfaction and continuous improvement, Aluminum Backer Pad is poised to remain a trusted partner for professionals in the industry.

Different Types of Grinding Wheels: A Complete Guide

Title: Exploring the Different Types of Grinding Wheels Revolutionizing Industrial ApplicationsIntroduction:In today's industrial revolution, grinding wheels play a fundamental role in various sectors, including manufacturing, construction, automotive, and metalworking. These indispensable tools are crucial for precision cutting, shaping, and finishing, enabling businesses to enhance productivity and achieve superior workpiece quality. This article aims to shed light on the various types of grinding wheels available in the market and their importance in revolutionizing industrial applications.1. Straight Grinding Wheels:Straight grinding wheels, also known as Type 1 wheels, are the most common and straightforward type used for surface grinding. These wheels have a flat outer periphery and deliver precise grinding performance on flat surfaces. Typically made from aluminum oxide or silicon carbide abrasive grains, straight grinding wheels are versatile and suitable for a wide array of materials, including steel, cast iron, brass, and non-ferrous metals.2. Cylinder Wheels:Cylinder wheels, designated as Type 2 wheels, possess a unique shape resembling a straight grinding wheel with a cylindrical face. These wheels are primarily used for grinding cylinders, bearings, and other rounded surfaces. The rounded design allows for easy and efficient grinding with reduced friction, resulting in excellent surface finishes.3. Tapered Grinding Wheels:Tapered grinding wheels, commonly referred to as Type 4 wheels, are specially designed for grinding operations that require precision and control. These wheels have a tapered shape, gradually narrowing towards the arbor hole. The tapering enables the wheel to penetrate the workpiece effectively, making them ideal for intricate grinding tasks such as internal grinding.4. Dish Grinding Wheels:Dish grinding wheels, known as Type 11 wheels, possess a dish-shaped design with a roundish outer rim and a depressed center. These wheels are widely used for contour grinding, grinding complex shapes, and removing excess material from the workpiece. The recessed center allows for a higher degree of flexibility, making them suitable for both large and small-scale applications.5. Diamond Wheels:Diamond grinding wheels are the epitome of grinding wheel technology, offering exceptional hardness, durability, and precision. Utilizing diamond abrasives, these wheels excel in cutting and grinding extremely hard materials such as carbides, ceramics, glass, and stones. Their fine grit allows for a smooth finish and minimal material wastage, making diamond wheels ideal for demanding applications.6. CBN Wheels:Cubic Boron Nitride (CBN) grinding wheels are similar to diamond wheels in terms of their exceptional hardness and longevity. These wheels are specifically formulated for grinding ferrous materials, including hardened steels and cast iron. With their heat resistance and ability to retain sharpness, CBN wheels are perfect for high-speed grinding operations, resulting in improved productivity and reduced downtime.Conclusion:Grinding wheels are indispensable tools in the industrial sector, revolutionizing various applications, from metalworking to automotive and construction. This article explored different types of grinding wheels, highlighting their characteristics and applications. The versatility and precision offered by these wheels allow businesses to improve productivity, achieve superior workpiece quality, and ultimately drive the industrial revolution forward. As technology advances further, we can expect the development of innovative grinding wheel types, continually pushing the boundaries of what can be achieved in industrial grinding.

Cup Wheel Grinding Discs: Enhancing Precision and Efficiency in Grinding Tasks

Cup Wheel Grinding Discs are among the most popular and versatile tools in the grinding and cutting industry. These discs are used for a wide range of applications including shaping, grinding, and polishing various surfaces. The grinding disc is primarily designed for use on concrete surfaces, but it is also effective on other surfaces such as stone, masonry, and metal.Leading manufacturers of grinding discs produce high-quality products that cater to the needs of professionals in diverse industries, which means that the company behind it is critical to ensure that you are investing in the right product. One of the top manufacturers and suppliers of Cup Wheel Grinding Discs in the market is {}, a leading company in the abrasives industry.Beginnings of {}{} was founded in 1999 with a mission to provide quality abrasives for the machinery industry. {} has since established itself as a leading supplier of abrasives and industrial tools in the market. The company focuses on delivering the highest quality product to their customers. They invest heavily in research and development to ensure that their products are the best in the market.{} has a team of skilled engineers who work closely with the research and development team to ensure that their products meet the highest standards of quality. The company operates in modern facilities equipped with advanced machinery and tools. This ensures that they meet established industry regulations and are always one step ahead of their competitors.In addition to its manufacturing capabilities, {} has an efficient distribution network that ensures its products are readily available to customers worldwide. The company has established strong partnerships with various distributors globally who work closely with them to serve their customers and meet their needs efficiently.Product RangeThe company produces a variety of grinding discs, but the Cup Wheel Grinding Discs are one of their most popular products. The Cup Wheel Grinding Disc is available in different materials and sizes, and it comes with different grit levels depending on the needs of the user.The diamond cup wheel grinding disc is designed for heavy-duty applications such as grinding concrete, granite, and marble surfaces. The diamond cup wheel grinding disc is fitted with a diamond impregnated section that can cut through the toughest surfaces, making it the perfect tool for professionals in the concrete and stone cutting fields.Moreover, the diamond cup wheel grinding disc is available in different shapes such as the single row, double row, and turbo style cup wheel, giving professionals the freedom to choose the one that suits their specific needs.Another popular product is the silicon carbide cup wheel grinding disc, which is perfect for use on stone surfaces such as marble and granite. The silicon carbide cup wheel grinding disc is a versatile tool that is known for its fast cutting performance and durability.ConclusionAs a professional in any field, investing in quality tools is critical to ensuring that your work is not only efficient but also of the highest quality. The Cup Wheel Grinding Disc from {} is a must-have in your arsenal. By investing in the Cup Wheel Grinding Disc, you are assured of a tool that is made to the highest standards of quality and performance.

High-Quality Nylon Wheel Brush for Drills at Affordable Prices

The demand for innovative and efficient cleaning tools has grown significantly in recent years, and one company at the forefront of meeting this demand is [Company Name]. The company has recently introduced a new product to its line of cleaning tools: the Nylon Wheel Brush for Drill.The Nylon Wheel Brush for Drill is designed to be attached to a power drill, transforming it into a powerful cleaning tool. The brush features durable nylon bristles that are tough on dirt and grime, yet gentle on surfaces, making it ideal for a wide range of cleaning applications. Whether it's removing rust and corrosion from metal surfaces, cleaning tires and rims, or scrubbing away stubborn stains from concrete, the Nylon Wheel Brush for Drill is up to the task.One of the key features of the Nylon Wheel Brush for Drill is its versatility. It is compatible with most power drills, making it accessible to a wide range of users. Additionally, the brush is designed to be long-lasting, with the nylon bristles retaining their shape and performance over time. This ensures that users can rely on the brush for consistent and effective cleaning results.[Company Name] is well-known for its commitment to quality and innovation. With a focus on meeting the evolving needs of customers, the company has established itself as a leader in the cleaning tools industry. The introduction of the Nylon Wheel Brush for Drill is a testament to [Company Name]'s dedication to providing cutting-edge solutions for cleaning challenges.In addition to its innovative products, [Company Name] is also recognized for its excellent customer service. The company prides itself on its ability to provide knowledgeable and friendly support to customers, ensuring that they have a positive experience with [Company Name] products. This commitment to customer satisfaction has helped [Company Name] build a loyal and satisfied customer base.The Nylon Wheel Brush for Drill is just the latest example of [Company Name]'s dedication to delivering high-quality, effective cleaning tools. With its durable construction, versatile design, and compatibility with power drills, the brush is set to become a valuable addition to the cleaning arsenal of homeowners, contractors, and maintenance professionals alike."We are excited to introduce the Nylon Wheel Brush for Drill to our customers," said [Spokesperson Name], [Title] at [Company Name]. "This brush represents our ongoing commitment to providing innovative and effective cleaning solutions. We believe that it will make a valuable addition to any cleaning toolkit, and we are confident that our customers will be delighted with its performance."The Nylon Wheel Brush for Drill is now available for purchase through [Company Name]'s website and select retailers. With its arrival on the market, [Company Name] continues to solidify its position as a leading provider of high-quality cleaning tools.For customers who are seeking a reliable and efficient solution for their cleaning needs, the Nylon Wheel Brush for Drill is set to make a significant impact. With [Company Name]'s reputation for excellence and the brush's impressive features, it's clear that this product is poised to become a staple in the world of cleaning tools.

New Wire Brush Grinding Wheel Technology for Improved Grinding Performance

Wire brush grinding wheels are a must-have for anyone who wants to keep their metal materials in top condition. They are particularly useful in removing rust, paint, and other types of corrosion from the surface of metalwork. These wheels are designed to be used with a wide range of angle grinders and are easily adaptable for use in a variety of industrial settings.One company that produces high-quality wire brush grinding wheels is a leading manufacturer in the industry. They have been in the business of producing abrasive products for over 30 years, and they have built a reputation for themselves through their commitment to quality and their ability to customize their products to suit the unique needs of their customers.According to a company spokesperson, their wire brush grinding wheels are made from the highest quality materials. The wire bristles are constructed from tough, durable metal alloys that are specifically designed to withstand harsh industrial environments. Their wheels are also available in a range of different sizes and shapes, making them suitable for use with various types of angle grinders.One of the main advantages of using these wire brush grinding wheels is that they are highly versatile. They can be used for everything from cleaning up welds to preparing surfaces for painting or other types of finishing. They are also ideal for removing rust or any other type of corrosion.In addition to their quality products, the company also places a high value on customer service. This is evident in their ability to customize their products to meet the needs of each individual customer. Whether a client requires a specific size or shape of wheel, or they need a specialized type of wire bristle to suit their specific application, this company has the expertise and resources to deliver customized products that meet their customers' needs.Moreover, the company produces their wire brush grinding wheels in a highly efficient manner. This means that they are able to provide their customers with top-quality products at competitive prices. Whether a client needs a single wheel or a bulk order, they can be sure that they will receive a product that is both affordable and of the highest quality.Another key feature of these wire brush grinding wheels is their durability. The combination of high-quality materials and expert construction results in products that are built to last. They are able to withstand the rigors of heavy use and exposure to harsh environments, ensuring that they provide reliable performance for an extended period of time.Looking to the future, the company has ambitious plans to expand its operations and continue to innovate in the field of abrasive products. They are committed to staying at the forefront of their industry and providing their customers with the latest cutting-edge technology and techniques. They envision a future where their products are used in diverse industries around the world, cementing their position as a leading manufacturer of wire brush grinding wheels.In conclusion, wire brush grinding wheels are an essential tool for any industry that works with metal materials. They are highly versatile, durable, and efficient, making them the ideal choice for a range of applications. The products produced by this leading manufacturer stand out for their quality, customization, and affordability, making them a top choice for anyone in need of high-quality abrasive products. As the company continues to innovate and expand, it is sure to remain a key player in the industry for many years to come.

Discover the Benefits of Ceramic Flap Discs - A Versatile Abrasive Tool for Various Applications

Ceramic Flap Disc Revolutionizes Grinding and Polishing ApplicationsIn the ever-evolving world of manufacturing and fabrication, there is a constant demand for better tools and technologies that enhance efficiency and productivity. One such groundbreaking innovation, the Ceramic Flap Disc, is rapidly gaining popularity for its superior performance in grinding and polishing applications.Developed by an industry-leading manufacturer [], the Ceramic Flap Disc is designed to completely transform the way professionals approach abrasive processes. With its advanced composition and innovative design, this cutting-edge tool offers unprecedented advantages over traditional grinding and polishing solutions.The Ceramic Flap Disc incorporates a unique combination of high-quality abrasive grains and a strong resin bond system. This proprietary blend ensures exceptional durability, extended service life, and excellent material removal rates. The ceramic grains used in the disc have a well-defined shape and size, resulting in more consistent and precise results.One of the key features of the Ceramic Flap Disc is its outstanding toughness and versatility. It can effortlessly tackle various materials, including stainless steel, carbon steel, aluminum, and non-ferrous metals. This versatility makes it an invaluable tool for a wide range of industries, including automotive, aerospace, construction, and metal fabrication.The Ceramic Flap Disc's durability and long-lasting performance make it an ideal choice for heavy-duty applications. Its self-sharpening design ensures a consistent cutting action, minimizing downtime for tool changes and maximizing productivity. The innovative heat-resistant coating on the disc prevents overheating and extends its lifespan, ultimately reducing tooling costs for businesses.Moreover, the Ceramic Flap Disc offers exceptional stock removal capabilities, allowing professionals to complete their tasks more efficiently. Its aggressive grinding action combined with smooth finishing properties makes it a versatile solution for both rough and fine grinding applications. This versatility makes it an excellent choice for the removal of weld seams, scale, rust, and for surface preparation prior to coating or welding.Safety is of utmost importance in any industrial process, and the Ceramic Flap Disc excels in this aspect as well. It is designed with a reinforced fiberglass backing, ensuring enhanced stability and added safety during operation. The disc's ergonomic design also contributes to reduced operator fatigue, allowing for extended usage without compromising comfort.The Ceramic Flap Disc not only boasts exceptional performance, but it also offers environmental advantages. Its efficient material removal rates reduce the need for excess grinding, minimizing waste generation. Additionally, the long service life of the disc results in fewer replacements, further reducing the environmental impact.To cater to diverse customer preferences and requirements, the Ceramic Flap Disc is available in various sizes and grit options. This allows professionals to choose the most suitable disc for their specific applications, ensuring optimal results every time.In conclusion, the Ceramic Flap Disc is a game-changing solution for grinding and polishing tasks in the manufacturing and fabrication industry. With its unmatched performance, durability, and versatility, this revolutionary tool is challenging the status quo and setting new standards of excellence. Professionals across various industries can now achieve superior results in their abrasive processes, significantly improving their productivity and efficiency.