High-quality CBN grinding wheels for precision metal grinding

By:Admin

{Company Name} is a leading manufacturer of abrasive tools, specializing in the production of Diamond CBN Grinding Wheels. With years of experience and expertise in the industry, the company has built a strong reputation for delivering high-quality products that meet the specific requirements of their clients. Their cutting-edge manufacturing facilities and advanced technologies allow them to produce grinding wheels that are both durable and efficient.

The Diamond CBN Grinding Wheels offered by {company name} are known for their exceptional performance and reliability. These wheels are made using high-quality diamonds and cubic boron nitride, which are among the hardest materials available. This ensures that the wheels have a long lifespan and can withstand the most demanding grinding applications. In addition, they offer superior heat resistance and excellent abrasive properties, making them ideal for precision grinding processes.

One of the key features of {company name}'s Diamond CBN Grinding Wheels is their ability to provide high material removal rates while maintaining excellent surface finish. This is essential for achieving the desired precision and quality in the final product. The wheels are designed to deliver consistent results, allowing for increased productivity and cost savings for the end users.

In addition to their outstanding performance, {company name}'s Diamond CBN Grinding Wheels are also designed for ease of use and compatibility with a wide range of grinding machines. This makes them versatile and suitable for various grinding operations, including cylindrical grinding, surface grinding, and centerless grinding.

Moreover, {company name} takes pride in its commitment to sustainability and environmental responsibility. The manufacturing processes for their Diamond CBN Grinding Wheels are designed to minimize waste and energy consumption, while also ensuring the safety and well-being of their workers. This aligns with the company's vision of contributing to a greener and more sustainable future for the industry.

The market for Diamond CBN Grinding Wheels is expected to grow significantly in the coming years, driven by the increasing demand for high-precision grinding tools in various sectors. {Company name} is poised to capitalize on this opportunity by continuing to innovate and expand its product line to meet the evolving needs of its customers.

In conclusion, {company name} has established itself as a leading provider of Diamond CBN Grinding Wheels, renowned for their exceptional quality, performance, and reliability. With a strong focus on innovation and sustainability, the company is well-equipped to meet the growing demand for high-quality grinding tools in the global market. As they continue to push the boundaries of technology and manufacturing, {company name} is set to maintain its position as a trusted partner for businesses looking to achieve excellence in their grinding operations.

Company News & Blog

Discover Laser and Water Cutting: How It Works and Its Uses in Manufacturing and Engineering

Cutting is a widely used process in the manufacturing industry that involves the separation of materials into smaller pieces. There are several methods of cutting available, including sawing, milling, and drilling, but perhaps the most popular and efficient processes are laser cutting and water cutting.Both laser cutting and water cutting are computer-controlled methods that utilize high-tech systems to slice through materials with precision and speed. Here’s a closer look at how each of these processes works:Laser CuttingLaser cutting uses a high-powered laser beam to cut through materials such as metals, plastic, wood, and ceramics. The laser beam is directed by computer-controlled mirrors onto the material to be cut. The beam creates a localized area of intense heat that melts or vaporizes the material. The laser beam is then moved across the material to create the desired pattern or shape.One of the advantages of laser cutting is its high precision. Laser cutters are capable of cutting complex shapes with ultra-fine details. They can create sharp corners and intricate designs with minimal burring. Laser cutting is also faster and more efficient than traditional cutting methods.Laser cutting is used in a variety of applications, including industrial manufacturing, aerospace, automotive, medical, and electronics. It is ideal for cutting thin materials, and it can cut through a wide range of thicknesses, from a few micrometers to several centimeters. Laser cutting is also great for cutting reflective materials such as metals, which can be difficult to cut with traditional methods.Water CuttingWater cutting, also known as waterjet cutting, is a process that uses a high-pressure water stream to cut through materials. The water is pressurized to between 30,000 and 90,000 psi and then accelerated through a small orifice. The fast-moving water stream is then directed onto the material to be cut, typically through a nozzle.Waterjet cutting does not generate heat, making it ideal for cutting materials that are sensitive to heat, such as plastic, rubber, and foam. It can also cut through thick materials, up to several inches thick, with ease. Waterjet cutting is versatile and can be used with a variety of materials, including metals, stone, glass, and composites.One of the benefits of water cutting is its ability to cut through a wide range of materials without distorting or changing their properties. It can also cut through materials with irregular shapes and sizes. Water cutting is an environmentally-friendly process and does not generate any hazardous waste.ConclusionCutting is a crucial process in the manufacturing industry, and laser cutting and water cutting are two of the most efficient and versatile methods of cutting available today. Laser cutting uses a high-powered laser beam to cut through materials, while water cutting uses a high-pressure water stream. Both methods are computer-controlled and are ideal for cutting a wide range of materials and thicknesses. Cutting saw and other traditional cutting methods are still in use but these two advanced methods offer greater precision and speed for modern manufacturing needs.

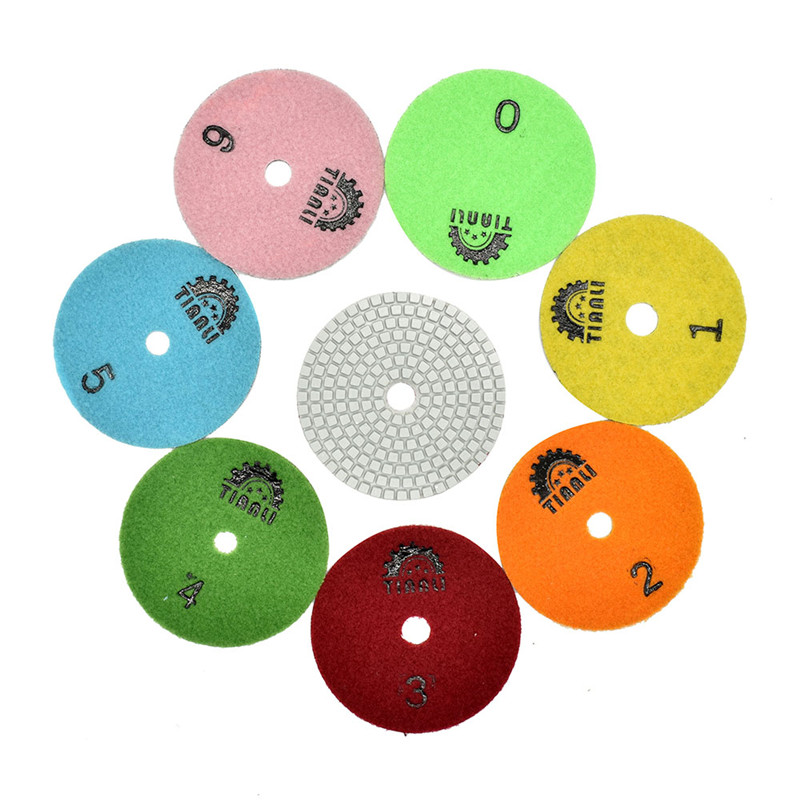

Find Reputed Polishing Pad Suppliers and Manufacturers - Import Easily from All Countries at buyindustrialtools.com

Polishing Pad: A Great Tool for Achieving a Mirror-Like FinishA polishing pad is an essential tool in the field of metalworking, woodworking, and automotive repair. It is used to achieve a mirror-like finish on surfaces of different materials, including metal, wood, and plastics. Polishing pads are available in different sizes, shapes, and materials, each designed for specific applications. In this blog post, we will talk about polishing pads, their benefits, and how to choose the right one.What is a Polishing Pad?A polishing pad is a circular tool that attaches to an angle grinder, rotary tool, or drill. It consists of a foam or wool backing that holds the abrasive material. The foam or wool backing is essential for distributing and absorbing the pressure, preventing swirls, scratches, and gouges from forming on the surface being polished. The abrasive material can be diamond, aluminum oxide, or silicon carbide, depending on the hardness and thickness of the material being polished.Benefits of Using a Polishing PadUsing a polishing pad has several benefits, including:1. Smooth and Uniform Finish: A polishing pad can achieve a smooth and uniform finish on any surface, removing scratches, swirls, and blemishes.2. Time and Labor-Saving: Polishing pads are quick and efficient, saving time and labor costs. They can remove imperfections, stains, and oxidation quickly without damaging the surface.3. Versatility: Polishing pads can be used on various materials, including metal, wood, plastics, and painted surfaces, making them versatile tools for a range of applications.4. Consistent Results: Polishing pads produce consistent results, ensuring that the surface achieved is the same every time, which is essential for projects that require a uniform finish.Choosing the Right Polishing PadChoosing the right polishing pad is essential for achieving the desired results. Here are some factors to consider when selecting the right polishing pad for your project.1. Material being polished - Different materials require different types of polishing pads. For instance, a soft foam pad is ideal for polishing paint, while a wool pad is perfect for metal surfaces.2. Grit - The grit size determines the level of abrasiveness of the polishing pad. A fine grit of 800-1000 is ideal for achieving a mirror-like finish.3. Size - The size of the polishing pad should match the size of the surface being polished. A larger pad is ideal for polishing large surfaces, while a smaller pad is suitable for intricate details.4. Speed - The speed at which the polishing pad spins is essential for achieving the desired results. A higher speed produces a more aggressive cut, while a slower speed produces a finer finish.ConclusionA polishing pad is an essential tool for achieving a mirror-like finish on a range of materials. They are quick, efficient, and versatile, saving time and labor costs while producing consistent results. When choosing a polishing pad, consider factors such as the material being polished, the grit, size, and speed. Investing in a quality polishing pad is a sound investment that will provide excellent results for years to come. So, if you're looking to achieve a flawless finish, consider investing in a 100mm polishing pad. It is the perfect size for most applications and will produce a mirror-like shine on any surface.

High-Quality Abrasive Polishing Pads for a Flawless Finish

Abrasive polishing pads are an essential tool for achieving a smooth and polished finish on a variety of surfaces. Whether you are working on wood, metal, or even concrete, abrasive polishing pads are designed to efficiently remove imperfections and create a high-quality finish. One of the leading producers of abrasive polishing pads is a company that has been a trusted name in the industry for over 30 years. Their commitment to providing high-quality products and exceptional customer service has made them a go-to choice for professionals and DIY enthusiasts alike.With a wide range of polishing pads available, this company offers options for every application. From heavy-duty concrete polishing pads to delicate wood polishing pads, their products are designed to meet the needs of any project. They also offer a variety of pad sizes and configurations to ensure that customers can find the perfect fit for their specific requirements.In addition to offering a comprehensive range of abrasive polishing pads, this company is also dedicated to innovation. They continuously invest in research and development to improve their products and stay ahead of the curve in the industry. This commitment to innovation has led to the creation of cutting-edge polishing pads that offer superior performance and durability.One of the key factors that sets this company apart from its competitors is its stringent quality control measures. Every abrasive polishing pad undergoes rigorous testing to ensure that it meets the company's high standards for performance and longevity. This dedication to quality has earned the company a reputation for reliability and consistency, making them a top choice for professionals who demand the best.As a customer-focused company, this company also prioritizes providing exceptional service. Their knowledgeable and experienced team is always on hand to offer advice and assistance, helping customers to find the right polishing pads for their specific needs. Whether you are a seasoned professional or a first-time user, you can trust that you will receive the support you need to achieve the best results.Furthermore, this company is committed to sustainability and environmental responsibility. They strive to minimize their environmental impact by using eco-friendly materials and manufacturing processes. This commitment to sustainability not only benefits the environment but also ensures that customers can feel good about choosing abrasive polishing pads from this company.In conclusion, abrasive polishing pads are an indispensable tool for achieving a flawless finish on a wide range of surfaces. With their dedication to quality, innovation, and customer service, this company has established itself as a leader in the industry. Their comprehensive range of high-quality polishing pads, combined with their commitment to sustainability and exceptional service, make them the top choice for professionals and DIY enthusiasts alike. Whether you are working on a small project at home or a large-scale industrial application, you can trust that abrasive polishing pads from this company will meet and exceed your expectations.

High-Quality 7 Inch Hook And Loop Polishing Pad for Efficient Polishing

Introducing the New 7 Inch Hook And Loop Polishing Pad by {Company Name}{Company Name}, a leading provider of high-quality automotive and industrial tools, is excited to announce the launch of its latest addition to their product line - the 7 Inch Hook And Loop Polishing Pad. This new polishing pad is designed to provide professionals and DIY enthusiasts with a reliable and efficient tool for a variety of polishing and buffing applications.The 7 Inch Hook And Loop Polishing Pad is constructed with durable materials and precision engineering to ensure maximum performance and longevity. The hook and loop design allows for quick and easy attachment to a variety of power tools, making it versatile and practical for use in automotive, woodworking, and metalworking industries.One of the key features of the 7 Inch Hook And Loop Polishing Pad is its compatibility with a wide range of polishing compounds and buffing pads. This allows users to achieve a mirror-like finish on a variety of surfaces, including metal, plastic, and painted surfaces. The pad is also designed to reduce heat build-up during extended use, preventing damage to the workpiece and ensuring consistent results.In addition to its exceptional performance, the 7 Inch Hook And Loop Polishing Pad is designed with user comfort and safety in mind. The pad is engineered to minimize vibration and reduce fatigue during extended use, making it ideal for professional detailers and enthusiasts alike. The pad also features a durable construction that can withstand rigorous use in demanding work environments.As with all {Company Name} products, the 7 Inch Hook And Loop Polishing Pad is backed by the company's commitment to quality and customer satisfaction. The company prides itself on providing reliable tools that meet the needs of professionals and hobbyists alike, and the new polishing pad is no exception. With its combination of durability, performance, and versatility, the 7 Inch Hook And Loop Polishing Pad is sure to become an essential tool in any workshop or garage.{Company Name} is committed to providing innovative solutions for the automotive and industrial markets, and the introduction of the 7 Inch Hook And Loop Polishing Pad is a testament to that commitment. The company continues to invest in research and development to bring new products to market, and the new polishing pad is just one example of their dedication to meeting the evolving needs of their customers.In conclusion, the introduction of the 7 Inch Hook And Loop Polishing Pad by {Company Name} represents a significant milestone for the company and its commitment to providing high-quality tools for professionals and enthusiasts. With its durable construction, exceptional performance, and versatility, the new polishing pad is sure to become a valuable addition to any workshop or garage. Customers can expect the same level of quality and reliability that they have come to expect from {Company Name}, making the 7 Inch Hook And Loop Polishing Pad a must-have for anyone in need of a dependable polishing tool.

How to Achieve a Perfectly Polished Diamond Floor

Diamond Floor Polishing Company Shines in the Flooring IndustryDiamond Floor Polishing, a leading provider of floor polishing services, has been making waves in the flooring industry with their exceptional services and top-notch customer care. With a strong emphasis on quality and customer satisfaction, the company has quickly become a go-to choice for both residential and commercial customers looking to give their floors a brand-new look.Established in 2005, Diamond Floor Polishing has been committed to delivering the highest standard of floor polishing and restoration services. With a team of highly skilled technicians and state-of-the-art equipment, the company has earned a reputation for excellence in the industry. Their expertise extends to a wide range of flooring materials, including marble, granite, terrazzo, and concrete, making them a versatile and reliable choice for any floor polishing project.One of the key factors that set Diamond Floor Polishing apart from their competitors is their dedication to using environmentally friendly products and methods. As an environmentally conscious company, they prioritize the use of eco-friendly products and processes to minimize the impact on the environment. This commitment to sustainability has resonated with customers who are looking for a responsible and ethical approach to floor polishing.In addition to their commitment to environmental sustainability, Diamond Floor Polishing also places a strong emphasis on customer satisfaction. They understand that every customer has unique needs and preferences when it comes to their floors, and they take the time to listen and understand each customer's requirements. This personalized approach has earned them a loyal base of satisfied customers who continue to turn to Diamond Floor Polishing for all their floor polishing needs.The company's dedication to excellence and customer satisfaction has not gone unnoticed. They have received numerous accolades and awards for their outstanding service and commitment to quality. These accolades serve as a testament to their unwavering dedication to providing the best possible floor polishing services to their customers.Diamond Floor Polishing's success can also be attributed to their commitment to innovation and continuous improvement. They are constantly exploring new techniques, products, and equipment to stay ahead of the curve in the ever-evolving flooring industry. This dedication to innovation allows them to deliver cutting-edge solutions and ensure that their customers receive the best possible results.Furthermore, Diamond Floor Polishing takes great pride in their ability to handle projects of all sizes and complexities. Whether it's a small residential floor polishing job or a large commercial restoration project, their team has the expertise and resources to tackle any challenge with precision and efficiency. This versatility has made them a trusted partner for a wide range of customers, from homeowners to business owners and facility managers.As Diamond Floor Polishing continues to grow and expand their reach, they remain committed to upholding their core values of quality, customer satisfaction, and environmental responsibility. With a proven track record of excellence and a loyal customer base, they are poised to continue making a significant impact in the flooring industry for years to come.For anyone looking to give their floors a new lease on life, Diamond Floor Polishing stands out as a reliable and reputable choice. With a focus on quality, sustainability, and customer care, they have set the bar high for floor polishing companies everywhere. Whether it's a residential or commercial project, customers can trust Diamond Floor Polishing to deliver exceptional results and an unmatched level of service.

Understanding the Significance of Metal Organic Bonds in Chemistry

Metal Organic Bonds (MOB), also known as (brand name), are innovative chemical compounds that have revolutionized the construction and industrial sectors. These bonds are created through a unique chemical process that allows for greater strength, durability, and flexibility compared to traditional bonding agents. With their superior performance and environmental benefits, MOBs have quickly gained popularity in various industries and have become a go-to solution for many construction projects.(Company name) is a leading producer and supplier of Metal Organic Bonds, offering a wide range of high-quality products to meet the diverse needs of its customers. The company has been at the forefront of developing and improving MOBs, continuously investing in research and development to deliver cutting-edge solutions to the market.One of the key features of MOBs is their exceptional strength and durability. These compounds provide a more robust bonding capability, making them suitable for a wide range of applications, including bonding metals, composites, and other materials. This enhanced strength allows for the construction of more resilient and long-lasting structures, contributing to overall safety and stability in various industrial settings.Furthermore, MOBs offer unparalleled flexibility, enabling the bonding of materials with differing physical properties. This flexibility is crucial in construction projects, where different materials need to be combined without compromising the overall integrity of the structure. With MOBs, builders and manufacturers can achieve seamless integration of various components, ensuring a cohesive and reliable end product.In addition to their superior performance, Metal Organic Bonds also offer environmental benefits. These compounds are free from harmful chemicals and solvents, reducing the impact on the environment during the bonding process. As sustainability becomes an increasingly important consideration in the construction and industrial sectors, MOBs provide a responsible and eco-friendly alternative to traditional bonding agents.(Company name) is dedicated to ensuring the highest quality and safety standards for its MOBs. The company adheres to strict manufacturing processes and quality control measures to guarantee the reliability and performance of its products. Moreover, (Company name) actively collaborates with industry partners and regulatory bodies to stay up-to-date with the latest standards and requirements, ensuring that its MOBs consistently meet or exceed industry expectations.The versatility of Metal Organic Bonds makes them suitable for a wide range of applications, including automotive manufacturing, aerospace, marine construction, and renewable energy projects. The increasing demand for lightweight and durable materials in these industries has driven the adoption of MOBs as a preferred bonding solution. With their proven track record and exceptional performance, (Company name) has established itself as a trusted supplier for these and many other industries.As the global market for Metal Organic Bonds continues to expand, (Company name) is committed to furthering its research and development efforts to innovate new and improved bonding solutions. By leveraging its expertise and industry knowledge, the company aims to address evolving market needs and deliver advanced products that set new standards for performance, sustainability, and reliability.In conclusion, Metal Organic Bonds have become an indispensable component in modern construction and industrial applications. The unique properties of MOBs, including superior strength, flexibility, and environmental benefits, have positioned them as a preferred choice for a wide range of projects. With (Company name) leading the way in developing and supplying high-quality MOBs, the industry can expect continued advancements and innovations that will shape the future of bonding technology.

New Wire Brush Grinding Wheel Technology for Improved Grinding Performance

Wire brush grinding wheels are a must-have for anyone who wants to keep their metal materials in top condition. They are particularly useful in removing rust, paint, and other types of corrosion from the surface of metalwork. These wheels are designed to be used with a wide range of angle grinders and are easily adaptable for use in a variety of industrial settings.One company that produces high-quality wire brush grinding wheels is a leading manufacturer in the industry. They have been in the business of producing abrasive products for over 30 years, and they have built a reputation for themselves through their commitment to quality and their ability to customize their products to suit the unique needs of their customers.According to a company spokesperson, their wire brush grinding wheels are made from the highest quality materials. The wire bristles are constructed from tough, durable metal alloys that are specifically designed to withstand harsh industrial environments. Their wheels are also available in a range of different sizes and shapes, making them suitable for use with various types of angle grinders.One of the main advantages of using these wire brush grinding wheels is that they are highly versatile. They can be used for everything from cleaning up welds to preparing surfaces for painting or other types of finishing. They are also ideal for removing rust or any other type of corrosion.In addition to their quality products, the company also places a high value on customer service. This is evident in their ability to customize their products to meet the needs of each individual customer. Whether a client requires a specific size or shape of wheel, or they need a specialized type of wire bristle to suit their specific application, this company has the expertise and resources to deliver customized products that meet their customers' needs.Moreover, the company produces their wire brush grinding wheels in a highly efficient manner. This means that they are able to provide their customers with top-quality products at competitive prices. Whether a client needs a single wheel or a bulk order, they can be sure that they will receive a product that is both affordable and of the highest quality.Another key feature of these wire brush grinding wheels is their durability. The combination of high-quality materials and expert construction results in products that are built to last. They are able to withstand the rigors of heavy use and exposure to harsh environments, ensuring that they provide reliable performance for an extended period of time.Looking to the future, the company has ambitious plans to expand its operations and continue to innovate in the field of abrasive products. They are committed to staying at the forefront of their industry and providing their customers with the latest cutting-edge technology and techniques. They envision a future where their products are used in diverse industries around the world, cementing their position as a leading manufacturer of wire brush grinding wheels.In conclusion, wire brush grinding wheels are an essential tool for any industry that works with metal materials. They are highly versatile, durable, and efficient, making them the ideal choice for a range of applications. The products produced by this leading manufacturer stand out for their quality, customization, and affordability, making them a top choice for anyone in need of high-quality abrasive products. As the company continues to innovate and expand, it is sure to remain a key player in the industry for many years to come.

New Study Reveals the Power of Metallic Sodium Bonds

Metallic sodium bonds are playing a significant role in the field of chemical research and innovation. The unique properties of metallic sodium bonds have caught the attention of scientists and engineers across the globe. This groundbreaking discovery has opened up a new world of possibilities for various industries, including energy, healthcare, and manufacturing.One company that has been at the forefront of exploring the potential of metallic sodium bonds is {remove brand name}. With a strong focus on research and development, {remove brand name} has been working tirelessly to harness the power of metallic sodium bonds and integrate them into practical applications.{remove brand name} is a leading chemical company that has made significant strides in the field of materials science and chemistry. The company has a rich history of innovation and has consistently pushed the boundaries of what is possible in the world of chemical engineering. With a team of top-notch scientists and researchers, {remove brand name} has been able to stay ahead of the curve and anticipate the next big breakthrough in the industry.The discovery of metallic sodium bonds has been a game-changer for {remove brand name}. The company has recognized the potential of this new development and has invested heavily in research and development to explore the various applications of metallic sodium bonds. From creating new materials with enhanced properties to developing advanced energy storage solutions, {remove brand name} has been at the forefront of pioneering groundbreaking innovations using metallic sodium bonds.One of the key areas where {remove brand name} has been focusing its efforts is in the development of high-performance batteries. Metallic sodium bonds have shown immense potential for improving the efficiency and performance of batteries, making them an ideal candidate for next-generation energy storage solutions. With the global demand for energy storage on the rise, {remove brand name} has been proactive in capitalizing on the opportunities presented by metallic sodium bonds.In addition to energy storage, {remove brand name} has also been exploring the use of metallic sodium bonds in the field of healthcare. The unique properties of metallic sodium bonds have opened up new possibilities for drug delivery systems and medical devices. By leveraging the power of metallic sodium bonds, {remove brand name} is committed to revolutionizing the healthcare industry and improving the quality of patient care.Furthermore, {remove brand name} has been collaborating with partners in the manufacturing sector to explore the use of metallic sodium bonds in the development of advanced materials. From lightweight alloys to high-strength composites, metallic sodium bonds have the potential to enhance the performance and durability of various materials used in manufacturing. {remove brand name} has been actively working with industry leaders to bring these innovative materials to the market and drive the next wave of industrial advancement.As a responsible corporate citizen, {remove brand name} is committed to ensuring the safe and sustainable use of metallic sodium bonds. The company places a strong emphasis on environmental stewardship and is dedicated to developing eco-friendly solutions that leverage the power of metallic sodium bonds without compromising on safety or sustainability. By adhering to rigorous quality and safety standards, {remove brand name} is paving the way for a future where metallic sodium bonds can be used responsibly for the betterment of society.In conclusion, the discovery of metallic sodium bonds has opened up a world of possibilities for various industries, and {remove brand name} is at the forefront of unlocking the potential of this groundbreaking development. With a strong focus on research and development, {remove brand name} is committed to harnessing the power of metallic sodium bonds and integrating them into practical applications that will shape the future of the chemical and materials science industry. As the world continues to evolve, {remove brand name} is poised to lead the way in driving innovation and advancing the frontiers of science and technology through the power of metallic sodium bonds.

High-Quality Final Buff Pad for Diamond Polishing

The Diamond Final Buff Pad is a revolutionary new product that will change the way you approach buffing and polishing for good. Designed and developed by a team of experts at our company, this innovative pad is set to redefine industry standards and set a new benchmark for performance and quality.At our company, we are committed to pushing the boundaries of what is possible in the world of automotive and industrial detailing. With a dynamic team of engineers, designers, and industry professionals, we strive to create products that not only meet, but exceed, the needs and expectations of our customers. The Diamond Final Buff Pad is a testament to this commitment, and it represents the culmination of extensive research, development, and testing.Our team identified a gap in the market for a buff pad that could deliver consistently exceptional results, without compromising on durability or ease of use. This led to the development of the Diamond Final Buff Pad, which is crafted using the highest quality materials and cutting-edge technology. The result is a product that is not only highly effective at removing imperfections and achieving a flawless finish, but also incredibly durable and resistant to wear and tear.One of the key features of the Diamond Final Buff Pad is its advanced composition, which allows for maximum performance and longevity. Unlike traditional buff pads, which may degrade over time and lose their effectiveness, the Diamond Final Buff Pad maintains its integrity and performance throughout extended periods of use. This means that users can achieve consistently exceptional results, time and time again, without having to worry about the pad wearing out or becoming less effective.Furthermore, the Diamond Final Buff Pad is engineered to be incredibly user-friendly, making it suitable for both professionals and hobbyists alike. Its lightweight design and ergonomic shape ensure that it is easy to handle and maneuver, while its intuitive application process requires minimal effort and skill. This makes the Diamond Final Buff Pad accessible to a wide range of users, from experienced detailers to DIY enthusiasts, who can all benefit from its exceptional performance and ease of use.In addition to its practical benefits, the Diamond Final Buff Pad is also designed with environmental sustainability in mind. We are committed to reducing our environmental impact and minimizing waste, which is why the pad is crafted from eco-friendly materials and is fully recyclable. This means that users can enjoy the exceptional performance of the Diamond Final Buff Pad, knowing that they are also making a positive contribution to the environment.Overall, the Diamond Final Buff Pad is set to revolutionize the world of buffing and polishing, offering a level of performance, durability, and user-friendliness that is unmatched by any other product on the market. Its advanced composition, user-friendly design, and environmental sustainability make it a standout choice for anyone looking to achieve exceptional results with minimal effort and maximum peace of mind.In conclusion, the Diamond Final Buff Pad represents the epitome of our company's commitment to innovation, quality, and sustainability. We are proud to introduce this groundbreaking new product to the market and we believe that it will set a new standard for buffing and polishing, while also making a positive impact on the environment. Whether you are a professional detailer or a hobbyist, the Diamond Final Buff Pad is sure to exceed your expectations and deliver exceptional results every time.

High-Quality Diamond Polishing Pads for Dry Polishing - The Latest in Polishing Technology

Introducing the Next Generation of Dry Diamond Polishing PadsIn the world of stone and concrete polishing, one company is making waves with their innovative new product: the Dry Diamond Polishing Pads. This revolutionary new system is changing the game for contractors and DIY enthusiasts alike, providing a faster, more efficient, and environmentally friendly way to achieve the perfect polished finish. With its unique design and superior performance, these pads are quickly becoming a favorite among industry professionals.The Dry Diamond Polishing Pads are the brainchild of {}. As a leading manufacturer of diamond tools and abrasives, they have built a reputation for providing high-quality products that deliver exceptional results. With over 20 years of experience in the industry, they have consistently pushed the boundaries of innovation, and their latest offering is no exception.The Dry Diamond Polishing Pads are specifically designed for dry polishing applications, making them a versatile and convenient choice for a wide range of projects. Whether working with natural stone, concrete, granite, or marble, these pads provide a high level of performance and durability, ensuring a smooth and consistent finish every time.One of the key features that sets these pads apart is their diamond matrix technology, which allows for superior cutting and polishing efficiency. This means that users can achieve excellent results in less time, without compromising on the quality of the finish. Additionally, these pads are designed to produce less dust and debris, creating a safer and cleaner working environment for the user.In addition to their impressive performance, the Dry Diamond Polishing Pads are also environmentally friendly. By eliminating the need for water during the polishing process, they help to reduce water consumption and waste, making them a sustainable choice for environmentally conscious users.To further enhance their versatility, these pads are available in a wide range of grit sizes, allowing users to achieve their desired level of polish with ease. This makes them suitable for both coarse and fine polishing applications, giving users the flexibility to tackle a variety of projects with just one set of pads.Committed to delivering the highest level of quality, {} has rigorously tested and refined the Dry Diamond Polishing Pads to ensure that they meet the demands of professional contractors and DIY enthusiasts alike. Their dedication to innovation and excellence shines through in every aspect of the design and performance of these pads, making them a must-have tool for anyone in the stone and concrete polishing industry.Upon its release, the Dry Diamond Polishing Pads have received an overwhelmingly positive response from industry professionals. Contractors and skilled tradespeople have praised the pads for their exceptional performance and ease of use, noting that they have significantly improved their efficiency and productivity on job sites. DIY enthusiasts have also embraced the pads for their user-friendly design and outstanding results, giving them the confidence to tackle their own projects with professional-level precision.As the demand for high-quality, efficient, and sustainable polishing solutions continues to grow, the Dry Diamond Polishing Pads from {} are poised to become an industry standard. With their cutting-edge technology, superior performance, and commitment to environmental responsibility, these pads are redefining the way that stone and concrete are polished, setting a new benchmark for excellence in the industry. For anyone seeking a reliable, versatile, and environmentally conscious polishing solution, the Dry Diamond Polishing Pads are the clear choice.