High-Quality Polished Diamonds: A Guide to Buying

By:Admin

{Company Name} was founded with the mission to provide customers with the most exceptional diamonds and jewelry, handcrafted with expert precision and unmatched artistry. The company's dedication to quality and craftsmanship has earned them a reputation as a trusted and respected name in the industry.

The latest collection from {Company Name} features a breathtaking array of polished diamonds, each meticulously cut and polished to perfection. From dazzling solitaires to intricate diamond-encrusted designs, the collection showcases the company's unwavering dedication to creating timeless and elegant pieces that will be cherished for generations.

One of the standout pieces in the collection is a stunning diamond necklace, featuring a dazzling array of round and princess-cut diamonds set in a delicate white gold chain. The necklace is a true testament to the company's commitment to creating pieces that exude luxury and sophistication.

In addition to its exquisite diamonds, {Company Name} also offers a wide range of other jewelry, including earrings, bracelets, and engagement rings. Each piece is crafted with the utmost care and attention to detail, ensuring that customers receive only the highest quality jewelry.

The company's commitment to ethical sourcing and responsible practices is also evident in its latest collection. {Company Name} sources its diamonds from reputable suppliers who adhere to strict ethical standards, ensuring that each diamond is conflict-free and responsibly sourced.

{Company Name} also takes pride in its personalized customer service, offering clients the opportunity to customize and create their own unique pieces. Whether it's a custom engagement ring or a one-of-a-kind necklace, the company's expert craftsmen work closely with customers to bring their vision to life.

As a leader in the industry, {Company Name} is dedicated to staying ahead of the curve when it comes to design and innovation. The company continuously invests in the latest technology and machinery to ensure that its diamonds are cut and polished with the utmost precision, resulting in a brilliance and sparkle that is truly unparalleled.

With its latest collection, {Company Name} continues to solidify its position as a destination for discerning customers seeking the very best in luxury jewelry. From its commitment to quality and craftsmanship to its dedication to ethical practices, the company sets the standard for excellence in the world of polished diamonds.

In an industry where excellence and precision are paramount, {Company Name} continues to stand out as a shining example of what it means to create truly exceptional jewelry. With its latest collection, the company reaffirms its commitment to providing customers with diamonds and jewelry that are not only beautiful, but also enduring symbols of love and luxury.

Company News & Blog

Environmental group opposes air permit for $340M metal recycling and smelting plant

Augusta Metal Plant Wins Authorization for $760M in BondsAugusta's new metal recycling and secondary smelting facility has received authorization for $760 million in bonds from state authorities. This development marks a significant milestone in the construction of the world-class metal facility, which has been under development in Augusta for many months now.Construction of the plant has been on full swing for a while now, and the project is set to change Augusta's economy. The facility will result in the creation of several new jobs and provide significant economic benefits to the local communities.The Environmental ChallengeThe Savannah Riverkeeper submitted an argument against an air permit for the facility in July 2021. The environmental group fears that the new plant's emissions would cause health hazards to the local community.The permit requested by the plant was to allow it to emit up to 5,000 tons of carbon monoxide annually, which was well above the lower limits proposed by the Savannah Riverkeeper.To resolve these concerns, the facility's authorities agreed to impose stricter regulations for the plant's emissions by keeping the amount of carbon monoxide below 2,500 tons per year.Assuming that the metal recycling and secondary smelting facility will adhere to regulations, it could prove to be a significant asset to the various companies that depend on scrap metal.Benefits of the Metal Recycling and Secondary Smelting FacilityThe new facility will utilize scrap metal and turn it into valuable items- thereby reducing the reliance on non-renewable resources and minimizing the products that end up in landfills.The facility is expected to generate more than 200 well-paying jobs, with a majority going to individuals living in the Augusta area, thus improving the local economy.Moreover, the plant's development will create new trade and supply chain opportunities, meaning that the local market will see an increase in demand, which is expected to cause further economic growth.The authorities have agreed that the facility will be one of the most environmentally sustainable in the world, with a waste-free operation standard. The facility's management team has committed to ensuring that the plant's process is environmentally friendly, and they will monitor it regularly to minimize any environmental impact.Final TakeawayThe authorization of the $760 million in bonds marks a significant step forward for the Augusta facility. The plant is expected to be operational by mid-2022 and will provide a critical infrastructure to Augusta's economy.With all environmental concerns addressed, Augusta's metal recycling and secondary smelting facility has the potential to create a significant economic impact on the local communities while minimizing the facility's footprint on the environment.The metal recycling plant will provide an excellent source of sustainable energy, and with its promise of a waste-free operation, it is expected to set new standards in the metal recycling industry.If Augusta's metal recycling and secondary smelting facility upholds its commitment to sustainable practices, it is bound to grow into a major industry player, providing a diverse range of sustainable solutions. With all these planned developments, it's an exciting time for Augusta, and there is much to look forward to.

Understanding the Basics of Metallic Bond Chemical Bonds

Metallic Bond Chemical Bonds, a leading chemical company specializing in the production of high-quality metallic bonds for various industrial applications, has recently announced the launch of its latest line of advanced metallic bonding agents. These cutting-edge chemical compounds are designed to provide exceptional bonding strength and durability for a wide range of metal-based materials, making them an ideal choice for use in industries such as automotive, aerospace, construction, and manufacturing.With a strong focus on innovation and continuous improvement, Metallic Bond Chemical Bonds has dedicated significant resources to research and development in order to create the most effective and reliable metallic bonding solutions on the market. The company's team of experienced chemists and engineers have worked tirelessly to develop a proprietary formulation that offers superior adhesion and performance, setting a new standard for quality and effectiveness in the industry.One of the key advantages of Metallic Bond Chemical Bonds' latest products is their ability to form strong, long-lasting bonds with a variety of metals, including steel, aluminum, copper, and titanium. This versatility makes them well-suited for a wide range of applications, from bonding metal components in automotive manufacturing to securing structural elements in architectural projects. In addition, these advanced metallic bonding agents are formulated to withstand extreme environmental conditions, including high temperatures, corrosive chemicals, and heavy mechanical loads, ensuring reliable performance in even the most demanding operating environments.In a statement, the company's CEO expressed great enthusiasm for the new product line, noting that the development of these advanced metallic bonding agents represents a significant milestone for Metallic Bond Chemical Bonds. "We are thrilled to introduce our latest line of metallic bonding solutions to the market," said the CEO. "These products are the result of years of dedicated research and development, and we are confident that they will set a new standard for performance and reliability in the industry. We believe that our customers will greatly benefit from the exceptional bonding strength and durability that our products offer."As part of the launch, Metallic Bond Chemical Bonds is offering comprehensive technical support and assistance to help customers integrate the new metallic bonding agents into their manufacturing processes. The company's team of experts is available to provide guidance on product selection, application techniques, and compatibility considerations, ensuring that customers can achieve optimal results with the new products.Furthermore, Metallic Bond Chemical Bonds has also emphasized its commitment to sustainability and environmental responsibility in the development and production of its metallic bonding agents. The company has implemented rigorous quality control processes and environmental management systems to minimize its environmental footprint and ensure that its products adhere to the highest standards of environmental performance.With its latest line of advanced metallic bonding agents, Metallic Bond Chemical Bonds is poised to further strengthen its position as a leading provider of high-performance chemical solutions for industrial applications. The company's unwavering dedication to innovation, quality, and customer satisfaction has earned it a strong reputation in the industry, and the introduction of these new products is expected to further solidify its standing as a trusted partner for businesses seeking advanced metallic bonding solutions.

Discover the Benefits of a Diamond Grind Stone for Superior Grinding Results

Title: Innovative Grinding Solution Offers Superior Precision: The Introduction of Diamond Grind Stone by [Company]Introduction (100 words):[Company] is proud to unveil its latest breakthrough in grinding technology – the Diamond Grind Stone. This revolutionary product represents a significant leap forward in precision grinding solutions, offering unparalleled performance and durability. With the aim to meet the evolving needs of professionals across industries, the Diamond Grind Stone combines cutting-edge diamond-enhanced technology with our years of expertise and commitment to quality. This latest addition to our portfolio reinforces [Company]'s position as an industry leader and shows our unwavering dedication to providing innovative solutions that empower our customers to achieve excellence in their work.Body:Paragraph 1 (100 words): The Diamond Grind Stone, designed and manufactured by [Company], is a game-changer when it comes to grinding applications. Its unique diamond-enhanced composition allows for exceptional abrasive performance, leading to faster material removal and increased productivity. With a focus on precision and longevity, the Diamond Grind Stone consistently delivers superior results, making it an ideal choice for a wide range of industries, including manufacturing, construction, and metalworking.Paragraph 2 (150 words):What sets the Diamond Grind Stone apart from conventional grinding stones is its advanced manufacturing process, which incorporates high-quality diamonds embedded in a matrix of durable materials. This ensures consistent abrasion and an extended lifespan, reducing the need for frequent replacements and saving valuable time and resources. The diamond-enhanced surface also provides a sharper cutting edge, optimizing cutting efficiency and minimizing heat generation during the grinding process. Additionally, the Diamond Grind Stone offers exceptional wear resistance, allowing it to handle the toughest grinding tasks while maintaining its performance over time.Paragraph 3 (150 words):Safety is a paramount consideration in any grinding operation, and the Diamond Grind Stone addresses this concern through its exceptional stability and balance. The design of the stone incorporates precision-engineered features, such as non-slip grips and a well-balanced composition, to provide users with maximum control and maneuverability. This ensures that operators can efficiently complete grinding tasks while minimizing the risk of accidents or fatigue. The optimized ergonomics of the Diamond Grind Stone further contribute to enhanced safety, making it a preferred choice for professionals across various industries.Paragraph 4 (200 words):[Company]'s commitment to customer service extends beyond the innovative technology of the Diamond Grind Stone. Every purchase is backed by comprehensive customer support, ensuring that users receive the assistance and guidance they need. Our team of industry experts is readily available to provide technical expertise, addressing any queries or concerns regarding the Diamond Grind Stone. We believe in building strong relationships with our customers, offering ongoing support and personalized recommendations to achieve the best possible grinding results for their specific applications.Conclusion (100 words):The introduction of the Diamond Grind Stone by [Company] revolutionizes the grinding industry by offering a superior grinding solution that combines precision, durability, and safety. Backed by years of expertise, [Company] continues to push boundaries in the pursuit of excellence, empowering professionals to achieve outstanding results. The Diamond Grind Stone's diamond-enhanced composition ensures faster material removal, exceptional longevity, and optimized safety, thus enhancing productivity and reducing downtime for users across various industries. With the unparalleled support offered by [Company]'s dedicated team, customers can trust in our commitment to their success.

High-Quality Diamond Polishing Pad Complete Set for Wet and Dry Surfaces

Introducing the Complete Set Wet/Dry Diamond Polishing Pad[Company Name], an industry leader in diamond tools and equipment, is proud to announce the launch of the highly anticipated Complete Set Wet/Dry Diamond Polishing Pad. This revolutionary product is set to revolutionize the polishing industry with its advanced technology and superior performance.The Complete Set Wet/Dry Diamond Polishing Pad is designed to provide professional results for a wide range of applications, including granite, marble, stone, and concrete. Whether you are a professional contractor or a DIY enthusiast, this set is the perfect solution for achieving a flawless finish every time.The set includes four high-quality polishing pads, each specifically designed for wet or dry use. This versatility allows users to tackle any project with ease, whether it's a small DIY job or a larger professional project. The pads are engineered to deliver exceptional results on both flat and curved surfaces, making them ideal for a variety of applications.One of the standout features of the Complete Set Wet/Dry Diamond Polishing Pad is its long-lasting durability. Each pad is constructed using premium diamond particles, which are bonded to a flexible backing for maximum strength and efficiency. This ensures that the pads maintain their performance and integrity throughout the entire polishing process, even under heavy use.Additionally, the pads are designed with a unique pattern that allows for efficient water flow and heat dissipation. This not only extends the lifespan of the pads but also helps to prevent overheating and glazing, resulting in a consistently smooth and polished surface.Another key advantage of the Complete Set Wet/Dry Diamond Polishing Pad is its user-friendly design. The pads are easy to attach to a variety of polishing tools, including angle grinders, polishers, and sanders, making them compatible with a wide range of equipment. This flexibility and ease of use make the set a valuable addition to any toolkit, whether for professionals or hobbyists.In addition to its exceptional performance, the Complete Set Wet/Dry Diamond Polishing Pad is also backed by [Company Name]'s commitment to quality and customer satisfaction. With years of industry experience, the company has established a reputation for delivering top-of-the-line products and unparalleled customer support."We are thrilled to introduce the Complete Set Wet/Dry Diamond Polishing Pad to the market," says [Company Name]'s spokesperson. "We have put a great deal of research and development into creating a product that not only meets but exceeds the expectations of our customers. We are confident that this set will deliver exceptional results for a wide range of polishing applications."Whether you are a professional contractor looking for a reliable polishing solution or a DIY enthusiast seeking professional-quality results, the Complete Set Wet/Dry Diamond Polishing Pad is the perfect choice. With its advanced technology, durable construction, and user-friendly design, this set is sure to become an indispensable tool in any workshop or job site. [Company Name] is proud to offer this innovative product, further solidifying its position as a leader in the diamond tools and equipment industry.

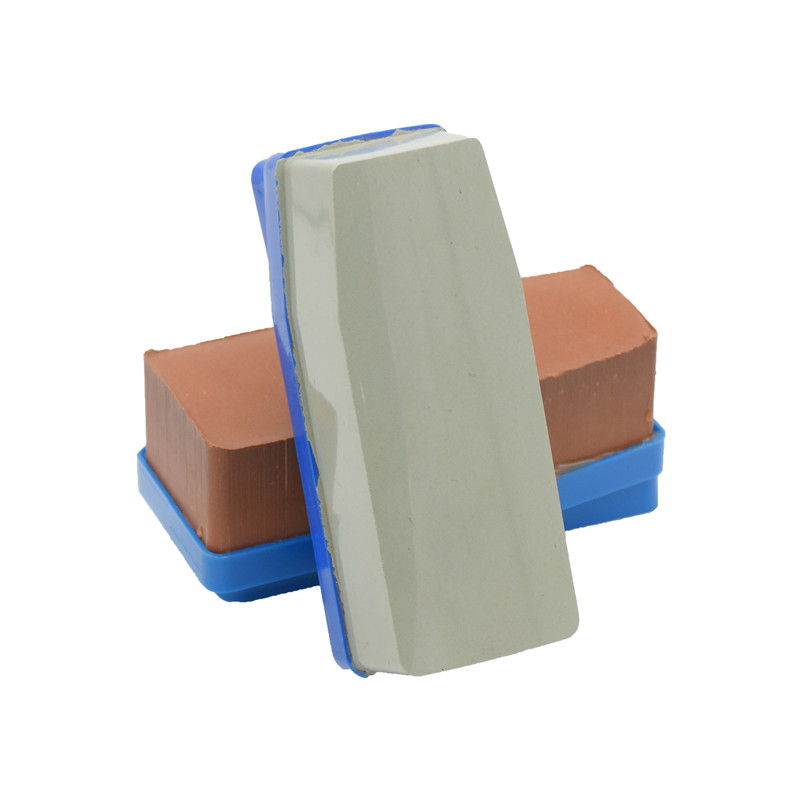

High-quality Ceramic Abrasive Tools for a Variety of Applications

Ceramic Abrasive Tools are revolutionizing the way industries approach cutting and grinding processes. This innovative tool is manufactured by a leading company specializing in abrasives, and has quickly gained a reputation for its superior performance and durability.The Ceramic Abrasive Tools are designed to outlast and outperform traditional abrasive materials such as aluminum oxide and silicon carbide. With its advanced ceramic grain technology, these tools offer exceptional cutting ability and long-lasting sharpness. This allows for increased productivity and cost savings for businesses that rely on precision cutting and grinding in their operations.The company behind these cutting-edge tools is a global leader in the abrasives industry. With over 50 years of experience, they have consistently pushed the boundaries of innovation to develop high-quality abrasives for a wide range of applications. Their commitment to research and development has enabled them to stay at the forefront of the industry, providing customers with the most advanced solutions for their cutting and grinding needs.In addition to the Ceramic Abrasive Tools, the company offers a comprehensive range of abrasive products, including grinding wheels, sandpaper, and coated abrasives. Their products are used in various industries, including manufacturing, aerospace, automotive, and metal fabrication. With a focus on quality and reliability, the company has built a strong reputation as a trusted partner for businesses seeking high-performance abrasives.The Ceramic Abrasive Tools have been particularly well-received in the metalworking industry, where precision cutting and grinding are critical processes. Metal fabricators and manufacturers have praised the tools for their ability to maintain sharpness and consistency over extended periods of heavy use. This has translated to significant cost savings for businesses, as the tools require less frequent replacement and deliver consistent results.One of the key advantages of the Ceramic Abrasive Tools is their ability to reduce heat generation during cutting and grinding. This is a crucial factor in preventing material deformation and maintaining the integrity of the workpiece. By minimizing heat buildup, the tools are able to produce smooth and precise cuts, leading to improved overall product quality.Furthermore, the Ceramic Abrasive Tools are engineered to reduce the occurrence of burrs and surface defects, resulting in a high-quality finish that meets the stringent standards of the industry. This level of precision is essential for businesses that produce components for critical applications, such as aerospace and medical devices.The company's commitment to sustainability is also evident in the manufacturing process of the Ceramic Abrasive Tools. By utilizing advanced materials and production techniques, they have minimized waste and reduced environmental impact. This aligns with the growing emphasis on sustainability and responsible manufacturing practices in the industry.As the demand for high-performance abrasives continues to grow, the Ceramic Abrasive Tools are expected to play a significant role in shaping the future of cutting and grinding processes. With their exceptional durability, precision, and environmental sustainability, these tools are poised to become the go-to choice for businesses seeking to maximize productivity and quality in their operations.In conclusion, the Ceramic Abrasive Tools represent a game-changing advancement in the field of abrasives, offering unmatched performance and reliability for a wide range of industries. Backed by a company with a proven track record of innovation and excellence, these tools are set to redefine the standards for cutting and grinding applications. As businesses continue to seek ways to improve efficiency and quality in their operations, the Ceramic Abrasive Tools are poised to become an indispensable asset in achieving these goals.

Understanding the Difference Between Nonmetal and Metal Bonds

Nonmetal and Metal Bonds: Revolutionizing the Aerospace IndustryAs technology continues to advance, the aerospace industry is constantly seeking innovative materials and methods to improve the performance of their products. One such advancement is the development of nonmetal and metal bonds, which has the potential to revolutionize the way aircraft components are manufactured and utilized.The use of nonmetal and metal bonds has been gaining traction in the aerospace industry due to their unique combination of properties, including high strength, light weight, and durability. These bonds are created through a process that involves the bonding of nonmetal materials, such as carbon fiber or ceramics, with metal alloys, resulting in a material that offers the best of both worlds.One company that has been at the forefront of this technology is {}. With a strong focus on research and development, {} has been able to create a range of nonmetal and metal bonded materials that are tailored to the specific needs of the aerospace industry. These materials have been met with enthusiasm from industry professionals and are expected to play a significant role in the future of aircraft manufacturing.The use of nonmetal and metal bonds has the potential to significantly reduce the weight of aircraft components, resulting in improved fuel efficiency and reduced carbon emissions. In addition, these materials offer greater strength and durability compared to traditional materials, which can contribute to increased safety and longevity of aircraft.Furthermore, nonmetal and metal bonded materials are also more resistant to corrosion and fatigue, reducing the need for frequent maintenance and repair. This can lead to cost savings for airlines and contribute to improved operational efficiency.{} has been working closely with aerospace manufacturers to integrate their nonmetal and metal bonded materials into various components of aircraft, including wings, fuselage, and engine parts. The company’s expertise in material science and engineering has allowed them to create tailored solutions that meet the stringent requirements of the aerospace industry.The development of nonmetal and metal bonded materials also aligns with the industry’s efforts to adopt more sustainable and environmentally friendly practices. By utilizing lightweight materials that improve fuel efficiency, aerospace companies can reduce their overall carbon footprint and contribute to a greener future for air travel.In addition to the benefits for aircraft manufacturing, nonmetal and metal bonded materials also have the potential to be utilized in other industries, such as automotive, construction, and renewable energy. This versatility makes them a valuable asset for companies like {} as they continue to explore new opportunities for their innovative materials.As the aerospace industry continues to evolve, the adoption of nonmetal and metal bonded materials is poised to become a transformative trend. With their numerous benefits and potential applications, these materials are set to play a crucial role in the development of next-generation aircraft and pave the way for a more sustainable and efficient future for air travel.With their expertise and dedication to innovation, {} is well-positioned to lead the charge in bringing nonmetal and metal bonded materials to the forefront of the aerospace industry. Their commitment to pushing the boundaries of material science and engineering will undoubtedly have a lasting impact on the industry and the way aircraft are designed and manufactured.

Durable Dry Grinding Disc for Granite: 0 to 6 Grit Options Available

**The New Innovative Dry Grinding Disc by {Company Name}**{Company Name}, a leading manufacturer of high-quality construction and industrial tools, has recently launched a new product that is set to revolutionize the dry grinding industry. The new Granite Dry Grinding Disc 0 to 6 is a game-changer in the field of grinding, offering unparalleled performance and durability.The innovative dry grinding disc is designed to meet the growing demands of the construction and industrial sectors, offering a solution for professionals seeking a reliable and efficient tool for their grinding needs. The disc is specially engineered to provide a smooth and consistent grinding experience, allowing for faster and more precise results.One of the key features of the Granite Dry Grinding Disc is its versatility. It is suitable for a wide range of materials, including granite, marble, and concrete, making it an essential tool for professionals working in various industries. The disc is also compatible with most standard grinding machines, making it easy to integrate into existing workflows.In addition to its versatility, the Granite Dry Grinding Disc is known for its exceptional durability. Constructed from high-quality materials, the disc is designed to withstand the rigors of heavy-duty use, ensuring that it can keep up with the demands of even the most challenging grinding tasks.The design of the disc also minimizes dust and debris, providing a cleaner and healthier work environment for professionals. This not only improves the working conditions but also contributes to a more efficient and productive grinding process.Furthermore, the innovative design of the Granite Dry Grinding Disc reduces heat generation during the grinding process, minimizing the risk of overheating and ensuring a longer lifespan for the disc. This ultimately translates to cost savings for professionals, as they can rely on the disc for extended periods without the need for frequent replacements.{Company Name} has a strong reputation for delivering high-quality products that meet the needs of professionals across the construction and industrial sectors. With a history of innovation and dedication to excellence, the company is committed to developing tools that improve the efficiency and effectiveness of their customers' work.The launch of the Granite Dry Grinding Disc is a testament to {Company Name}'s ongoing commitment to innovation and quality. By combining cutting-edge technology with the latest materials and manufacturing techniques, the company has once again raised the bar for the industry, providing professionals with a reliable and high-performance tool that meets their evolving needs.The introduction of the Granite Dry Grinding Disc has already garnered significant attention from professionals in the construction and industrial sectors. With its unmatched performance, durability, and versatility, the disc is poised to become an essential tool for professionals seeking a reliable and efficient solution for their grinding needs.As {Company Name} continues to expand its product range and push the boundaries of innovation, the launch of the Granite Dry Grinding Disc is yet another milestone in the company's journey towards excellence. With a focus on delivering the highest quality products and meeting the evolving needs of professionals, {Company Name} is set to remain a leading force in the construction and industrial tool industry for years to come.In conclusion, the Granite Dry Grinding Disc 0 to 6 represents a significant advancement in the field of dry grinding, offering professionals a reliable, efficient, and versatile tool for their grinding needs. With its exceptional performance, durability, and innovative design, the disc is set to become an essential addition to the toolkit of professionals across the construction and industrial sectors. As {Company Name} continues to lead the way in innovation and quality, the launch of the Granite Dry Grinding Disc further solidifies its position as a trusted provider of high-quality tools for professionals around the world.

High-Quality and Affordable Diamond Polishing Pads for Various Applications

- Importance of Diamond Polishing Pads for Stone RestorationStone restoration is a process that is becoming increasingly popular as people are realizing the benefits of restoring old and damaged stone surfaces. However, the process of stone restoration requires the use of specialized tools and equipment, including diamond polishing pads. These pads are specifically designed to restore stone surfaces to their original beauty and shine. In this blog post, we will discuss the importance of diamond polishing pads in stone restoration.Diamond polishing pads are designed to work with a wide variety of stone surfaces, including marble, granite, and other natural stone materials. They come in different sizes and grits to suit different types of stone surfaces and specific restoration needs. These pads are typically made of diamond-impregnated resin or metal-bonded diamond, which allows them to grind away the surface imperfections and smooth out the stone.The use of diamond polishing pads is an essential part of the stone restoration process. They are used to remove surface scratches, stains, and blemishes, as well as to bring out the natural beauty and shine of the stone. Diamond pads are also used to flatten uneven surfaces, smooth out rough edges, and to achieve a high-gloss finish.When selecting a diamond polishing pad for a stone restoration project, it is important to consider the type of stone surface being restored and the level of damage. The pads come in different grits, ranging from coarse to fine, and each grit is designed for a specific purpose. Coarse grit pads are used for heavy grinding and removing deep scratches and stains. Medium grit pads are used for smoothing out surface imperfections, and fine grit pads are used for achieving a high-gloss finish.In addition to using the appropriate grit, it is important to use the proper technique when using diamond polishing pads. Proper technique involves using a consistent amount of pressure and controlling the speed of the rotary tool. It is also important to use water or a special lubricating fluid to cool the pad and prevent it from overheating.In conclusion, the use of diamond polishing pads is crucial for restoring stone surfaces to their original beauty and shine. With the proper selection of grit, technique, and equipment, diamond pads can be used to remove scratches, stains, and imperfections, as well as to achieve a high-gloss finish. If you are considering a stone restoration project, be sure to work with a professional who understands the importance of using diamond polishing pads for the best results.

Newly Developed Disc Grinding Wheel Offers Superior Performance and Durability

Title: Advanced Disc Grinding Wheel - Boosting Precision and Efficiency in Various IndustriesIntroduction:Marching ahead with its commitment to innovation and excellence, [Company Name] has introduced an advanced Disc Grinding Wheel that promises to revolutionize the grinding industry. With its cutting-edge technology and superior design, this state-of-the-art grinding wheel delivers unparalleled precision and efficiency, catering to the diverse needs of multiple industries. In this article, we will delve into the features and benefits of the Disc Grinding Wheel while shedding light on how it is set to transform the landscape of grinding.Precise and Reliable Performance:The Disc Grinding Wheel, developed by [Company Name], offers an exceptional level of precision and reliability in grinding applications. Designed with meticulous attention to detail, this product ensures the highest standards of accuracy, making it a top choice for professionals across industries such as automotive, aerospace, metalworking, and more. The grinding wheel's innovative composition allows for consistent and uniform contact with the workpiece, resulting in a smooth finish with minimal tolerances.Enhanced Efficiency and Productivity:One of the key advantages of the Disc Grinding Wheel is its ability to enhance efficiency and productivity in grinding operations. Thanks to its advanced abrasive technology, this grinding wheel provides exceptional material removal rates, reducing the time required for grinding tasks. This efficiency not only boosts productivity but also reduces operational costs, making it a cost-effective solution for companies aiming to optimize their manufacturing processes.Durability and Longevity:[Company Name]'s Disc Grinding Wheel is built to withstand rigorous usage, ensuring long-lasting performance. Constructed with high-quality abrasives and reinforced materials, this grinding wheel offers exceptional durability even when used in intense grinding environments. Its robust composition minimizes the risk of deformation or breakage, ensuring consistent performance over extended periods of use. This durability translates into reduced downtime for maintenance and replacement, further increasing efficiency and productivity.Safe and User-Friendly:Safety is paramount in any industrial setting. Recognizing this, [Company Name] has prioritized the safety aspects of the Disc Grinding Wheel. With carefully engineered designs, this product offers a high level of user-friendliness, reducing the risk of accidents or injuries. Its ergonomic grip and vibration reduction technology ensure optimum control and comfort during operation, minimizing operator fatigue and enhancing overall safety.Wide Range of Applications:The versatile nature of the Disc Grinding Wheel allows it to excel in various industrial sectors. From surface grinding and edge rounding to deburring and polishing, this grinding wheel can handle a wide range of applications with exceptional efficiency and precision. Its adaptability and versatility make it suitable for use across diverse industries such as automotive, aerospace, construction, and more, ensuring a cost-effective and reliable solution for grinding needs in different sectors.Sustainability and Environmental Responsibility:In line with [Company Name]'s commitment to sustainability and environmental responsibility, the Disc Grinding Wheel adheres to strict eco-friendly manufacturing practices. Constructed with fewer abrasive materials, this grinding wheel minimizes waste generation and reduces environmental impact. Additionally, its longevity and durability further contribute to reducing material consumption and waste generation, positioning it as an environmentally conscious choice.Conclusion:With [Company Name]'s introduction of the advanced Disc Grinding Wheel, the grinding industry is poised to experience a significant transformation. Combining precision, efficiency, durability, and sustainability, this state-of-the-art product is set to redefine the standards of grinding performance. By catering to a wide range of industries and applications, it serves as a reliable and cost-effective solution for professionals seeking unparalleled results. [Company Name] continues to innovate and push boundaries, enabling companies to achieve new heights of productivity and quality in their grinding operations.

Metallic Diamond Abrasive Pads for Coarse Marble Grinding in UK Market

, Marble Polishing, Diamond Polishing Pads, Marble Abrasives, Diamond Metallic Frankfurt Abrasive PadWhen it comes to marble polishing, there is no denying that you need the right tools to accomplish the job. This is where Frankfurt Diamond Abrasives come in - they are one of the most effective and efficient tools for polishing marble.Frankfurt Diamond Abrasives are specially designed to polish marble, offering a unique abrasive surface that works to remove scuffs, scratches, and other imperfections on the stone's surface. This abrasive tool is manufactured with diamond crystals, which is why it has become such a popular option for those looking to polish marble.Marble Abrasives are specifically designed to work on marble surfaces, providing the perfect texture needed for a clean and polished finish. The use of abrasives in marble polishing is a must-have, as they help to remove any imperfections on the surface of the stone.Diamond Polishing Pads are also crucial for marble polishing, and they come in different grades of coarseness. The lower the grit number, the coarser the pad is, and the higher the grit number, the smoother the pad is. Using the correct grade of polishing pad is important, as it will determine the final look of the marble.One of the newest options for marble polishing comes in the form of Diamond Metallic Frankfurt Abrasive Pads. These pads use a combination of diamond crystal and metallic materials, which helps to achieve a polished and glossy finish easily. This new option has become increasingly popular in the UK market due to its effectiveness and efficiency.In conclusion, the use of Frankfurt Diamond Abrasives, Marble Polishing, Diamond Polishing Pads, Marble Abrasives, and Diamond Metallic Frankfurt Abrasive Pads have become necessary for a great marble polishing job. Using the right tools and techniques helps to achieve a polished and glossy finish on your marble surface, making it look brand new and elegant. When looking for the right tools to use in marble polishing, consider the products mentioned above, as they have proved to be the most effective and popular in the market.