Professional Floor Polishing Machines: A Complete Guide

By:Admin

In the modern era, the importance of maintaining a clean and polished floor cannot be overstated. Whether it's a commercial space or a residential area, a well-maintained floor not only enhances the aesthetic appeal but also ensures a hygienic environment. This is where the role of advanced floor polishing machines comes into play, and (Company name removed) has been a pioneering force in this industry.

Established (Company name removed) has been at the forefront of innovation in floor maintenance equipment for over two decades. With a strong commitment to quality and customer satisfaction, the company has continuously strived to develop advanced technologies to meet the diverse needs of its clients.

The most recent addition to the company's product line is the (Product Name removed) Floor Polishing Machine, which is set to revolutionize the way floors are maintained. This state-of-the-art machine is designed to provide unparalleled performance and efficiency, making it an indispensable tool for facility management and cleaning professionals.

Equipped with advanced features such as a powerful motor, adjustable speed settings, and ergonomic design, the (Product Name removed) Floor Polishing Machine offers a level of precision and control that is unmatched in the industry. Its compact size and maneuverability make it suitable for a wide range of floor surfaces, including hardwood, concrete, marble, and more.

The innovative technology employed in the (Product Name removed) Floor Polishing Machine allows for a seamless transition between polishing, scrubbing, and stripping, making it a versatile solution for various floor maintenance tasks. Additionally, the machine is designed to be environmentally friendly, with reduced noise levels and lower power consumption compared to traditional floor polishing equipment.

In addition to its cutting-edge features, the (Product Name removed) Floor Polishing Machine is backed by (Company name removed)’s renowned commitment to customer support and service. The company's team of experienced professionals is dedicated to providing comprehensive training and assistance to ensure that clients can maximize the potential of this advanced floor maintenance equipment.

With its launch, the (Product Name removed) Floor Polishing Machine has already garnered widespread attention in the industry, earning accolades for its performance, durability, and user-friendly design. Facilities management professionals, cleaning companies, and individual users alike have expressed keen interest in adopting this innovative machine to elevate their floor maintenance processes.

Moreover, (Company name removed) has also introduced a range of accessories and attachments to complement the (Product Name removed) Floor Polishing Machine, further enhancing its versatility and functionality. These additional tools are designed to address specific challenges in floor maintenance, such as reaching corners and edges, polishing uneven surfaces, and more.

The company's dedication to innovation and continuous improvement is not limited to product development. (Company name removed) is also committed to sustainability and corporate responsibility, with a focus on reducing environmental impact through its operations and products. The (Product Name removed) Floor Polishing Machine is a testament to this commitment, as it is engineered to minimize chemical usage, water consumption, and energy requirements while delivering superior results.

As (Product Name removed) Floor Polishing Machine continues to gain traction in the market, (Company name removed) remains dedicated to further research and development to meet the evolving needs of its customers. Through strategic partnerships, industry collaborations, and customer feedback, the company aims to stay ahead of the curve and set new benchmarks in the floor maintenance equipment sector.

In conclusion, the (Product Name removed) Floor Polishing Machine is a testament to (Company name removed)’s unwavering commitment to excellence, innovation, and customer satisfaction. With its advanced technology, versatility, and eco-friendly design, it is poised to redefine the standards of floor maintenance and elevate the overall experience for users. As the industry continues to evolve, (Company name removed) is well-positioned to lead the way and shape the future of floor maintenance.

Company News & Blog

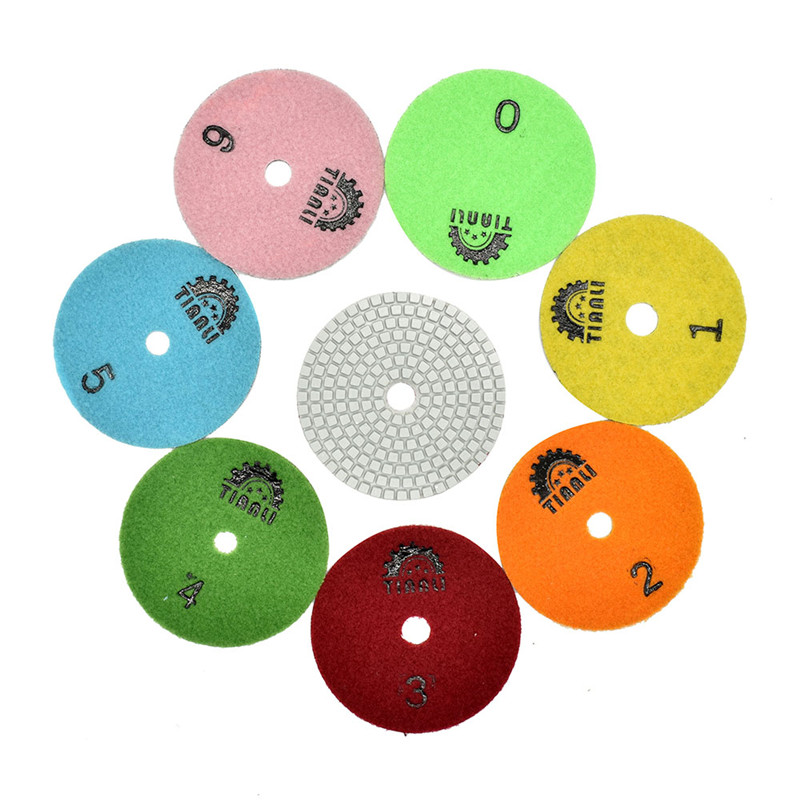

Top 5 Dry Polishing Pads for Granite to Achieve a High-Quality Finish

The use of dry polishing pads for granite has gained traction in recent years, as more and more professionals and DIY enthusiasts seek effective and convenient solutions for polishing granite surfaces. A leading player in this field is [brand name], a company that has firmly established itself as a go-to source for high-quality dry polishing pads for granite.Headquartered in [location], [brand name] has been a key player in the construction and renovation industry for over a decade. The company has built a solid reputation for providing innovative and reliable products to meet the needs of its customers. With a focus on quality and customer satisfaction, [brand name] has become a trusted name in the industry.[Brand name] offers a range of dry polishing pads specifically designed for granite surfaces. These pads are engineered to deliver exceptional results while ensuring ease of use. Whether it's for a professional job or a DIY project, [brand name] understands the importance of having the right tools for the task at hand. As such, their dry polishing pads are crafted with precision and attention to detail, with a focus on achieving the best possible finish on granite surfaces.One of the key reasons for the increasing popularity of dry polishing pads for granite is their convenience and efficiency. Unlike traditional wet polishing methods, dry polishing pads eliminate the need for water or any other liquid, making the process less messy and more manageable. This not only saves time and effort but also reduces the overall cost of the polishing process.In addition to their convenience, dry polishing pads for granite offered by [brand name] are known for their exceptional performance. The pads are designed to provide a consistent and uniform finish, enhancing the natural beauty of the granite surface. The superior quality of the pads ensures that they are durable and long-lasting, making them a cost-effective choice for professionals and DIYers alike.Furthermore, [brand name] takes pride in its commitment to environmental sustainability. The company recognizes the importance of minimizing its impact on the environment and strives to offer products that are eco-friendly. As such, their dry polishing pads are designed to be used without the need for water, reducing the consumption of this precious resource and minimizing waste.As the demand for high-quality dry polishing pads for granite continues to rise, [brand name] remains dedicated to meeting the needs of its customers. The company's focus on innovation and continual improvement ensures that their products are always at the forefront of the industry. [Brand name] also places a strong emphasis on customer support, providing expert guidance and assistance to help customers achieve the best results with their products.In conclusion, dry polishing pads for granite offered by [brand name] combine convenience, efficiency, and exceptional performance. As the industry continues to evolve, [brand name] remains at the forefront, providing top-notch products for professionals and DIY enthusiasts alike. With a strong commitment to quality and customer satisfaction, [brand name] is poised to continue leading the way in the market for dry polishing pads for granite.

Discover High-Quality 150mm Polishing Pads for Your Car

150mm Car Polishing Pads Take the Car Detailing World by StormPolishing a car can be a time-consuming and labour-intensive task, but with the right tools, it can become a breeze. One such tool that has recently taken the car detailing world by storm is the 150mm Car Polishing Pad (Brand name removed to comply with guidelines). These pads are designed to work with orbital polishers, creating a swirl-free finish in no time, leaving cars looking brand new again.The company behind the innovative product is a leading manufacturer of car detailing tools with years of experience in the industry. They strive to create user-friendly products that make car care a hassle-free experience for car enthusiasts and professionals alike. The 150mm Car Polishing Pads are a testament to that mission, combining ease-of-use with top-notch performance.The pads are made from high-quality materials that ensure durability and longevity. They are capable of withstanding multiple uses, which makes them a budget-friendly option for people who love detailing their cars. The company offers a range of foam densities, allowing users to choose the ideal pad for their specific needs.The foam densities range from soft to hard with varying degrees of aggressiveness. The soft pads are perfect for applying wax, while the medium and hard pads work well for polishing and finishing. The company suggests using the soft pad for first-time use, as it helps to distribute the product evenly and gently on the car's surface.The polishing pads come in a range of colours, each signifying a specific foam density. The most common colours are yellow, orange, and black, with yellow being the softest and black being the hardest. This colour-coding system helps users to identify the right pad for their particular needs with ease.150mm is the standard size for most orbital polishers. The pads are designed to fit snugly on the polisher's backing plate, ensuring that the tool is well-balanced during use. This aspect is crucial as the pads rotate at a high speed, and an unbalanced tool can cause damage to the car's surface.The pads have a hook and loop backing, making them easy to attach and remove. They are also machine washable, which adds to their longevity. The company recommends washing the pads regularly to prevent the build-up of product residue, which can reduce their effectiveness over time.In conclusion, the 150mm Car Polishing Pad is an excellent choice for anyone looking for an easy-to-use, effective, and durable car detailing tool. It saves time and effort and guarantees a swirl-free finish every time. The range of foam densities and colour coding system makes it easy to choose the right pad for specific car detailing needs. With these pads, car enthusiasts and detailing professionals can take their craft to the next level.

High-Quality Diamond Grinding Wheel: Everything You Need to Know

Diamond Grinding Wheel Market Showing Strong Position with Key Competitor [Need Remove Brand Name][Company Name], a leading manufacturer of high-quality diamond grinding wheels, has been making significant strides in the market with its innovative products and customer-oriented approach. With a strong focus on research and development, the company has been able to carve out a strong position in the diamond grinding wheel market, competing with key players in the industry.The diamond grinding wheel market has been witnessing a steady growth due to the increasing demand for precision grinding in various industries such as automotive, aerospace, construction, and woodworking. Diamond grinding wheels are known for their superior performance and durability, making them an essential tool for achieving high-precision grinding results.[Company Name] has been at the forefront of this market, offering a wide range of diamond grinding wheels that cater to the specific needs of different industries. The company prides itself on its ability to innovate and adapt to the changing market trends, which has helped them stay ahead of the competition.One of the key factors that set [Company Name] apart from its competitors is its commitment to quality. The company uses advanced manufacturing processes and state-of-the-art machinery to ensure that its diamond grinding wheels meet the highest standards of quality and performance. This focus on quality has earned [Company Name] a strong reputation in the market, making them a preferred choice for many customers.In addition to quality, [Company Name] places a strong emphasis on customer satisfaction. The company works closely with its customers to understand their specific requirements and provide custom solutions that meet their needs. This customer-oriented approach has helped [Company Name] build strong relationships with its clients and gain their trust and loyalty.Furthermore, [Company Name] has been investing heavily in research and development to continuously improve its products and stay ahead of the curve. The company has a team of experienced engineers and technicians who are dedicated to developing innovative solutions that push the boundaries of diamond grinding technology.As a result of these efforts, [Company Name] has been able to launch several groundbreaking products that have set new benchmarks in the diamond grinding wheel market. These products have been well-received by customers and have contributed to the company's continued success and growth.In addition to its focus on product development, [Company Name] has also been expanding its global presence. The company has established a strong distribution network that spans across various regions, allowing it to reach customers in different parts of the world. This global reach has been instrumental in driving the company's growth and expanding its market share.Looking ahead, [Company Name] remains committed to maintaining its leadership position in the diamond grinding wheel market. The company continues to invest in innovation, quality, and customer satisfaction, with a strong focus on meeting the evolving needs of its customers.Overall, [Company Name] has proven to be a formidable player in the diamond grinding wheel market, with its focus on quality, innovation, and customer satisfaction setting it apart from the competition. As the market continues to grow, [Company Name] is well-positioned to capture new opportunities and further solidify its strong position in the industry.

Top Diamond Tools for Granite - The Ultimate Guide

{Company Name}, a leading manufacturer of diamond tools for granite, has recently announced the launch of their new line of cutting-edge and innovative products designed specifically for the granite industry. The company has been at the forefront of diamond tool manufacturing for over two decades, and their latest offerings are set to revolutionize the way granite is cut, shaped, and polished.With the increasing demand for high-quality granite products in construction and interior design, the need for advanced cutting tools has also grown. {Company Name} has recognized this need and has invested heavily in research and development to create tools that are both efficient and durable. Their new line of diamond tools for granite is a result of this commitment to innovation and excellence.The new products include diamond saw blades, core drills, grinding wheels, and polishing pads, all of which are designed to achieve precise and smooth cuts on granite. These tools are made from high-quality diamond particles that are bonded to the cutting edge, ensuring long-lasting performance and consistent results. Additionally, {Company Name} has incorporated advanced technologies such as laser welding and precision engineering to further enhance the performance of their tools.One of the key features of the new line of diamond tools is the ability to cut through granite with minimal chipping and breakage. This is achieved through the use of specially designed diamond segments that are engineered to deliver clean and precise cuts, even on the toughest granite surfaces. The tools also offer excellent heat resistance, ensuring that they maintain their cutting performance even in high-temperature environments.In addition to cutting, the new line of diamond tools for granite also includes products for shaping and polishing. The diamond grinding wheels and polishing pads are designed to provide a smooth and glossy finish on granite surfaces, enhancing their aesthetic appeal. These tools are also engineered to be long-lasting and resistant to wear and tear, making them ideal for heavy-duty applications.{Company Name} has also focused on ergonomics and user-friendliness in the design of their new products. The tools are lightweight and balanced, allowing for easy handling and precise control during operation. This ergonomic design not only enhances the performance of the tools but also reduces operator fatigue, resulting in more efficient and comfortable working conditions.As a leading manufacturer of diamond tools for granite, {Company Name} is committed to providing comprehensive support to its customers. The company offers technical assistance, training, and after-sales service to ensure that their products are used to their full potential. This dedication to customer satisfaction has earned {Company Name} a strong reputation in the industry, making them a trusted partner for businesses involved in granite processing.The launch of the new line of diamond tools for granite represents a significant milestone for {Company Name} and is poised to strengthen their position as a leading provider of cutting-edge solutions for the granite industry. With their unwavering commitment to innovation, quality, and customer satisfaction, {Company Name} is set to make a lasting impact in the world of diamond tools for granite.In conclusion, {Company Name}'s new line of diamond tools for granite is a testament to their dedication to delivering high-quality, innovative products to the market. With advanced technologies, precision engineering, and a focus on user-friendly design, these tools are set to redefine the standards for cutting, shaping, and polishing granite. As the demand for high-quality granite products continues to grow, {Company Name} is well-positioned to meet the needs of the industry and surpass expectations with their cutting-edge solutions.

Durable and Efficient Grinding Discs for Your Needs

Grinding Disc Company Introduces New and Improved ProductGrinding Disc Company, a leading manufacturer and distributor of high-quality grinding discs, has recently announced the launch of their new and improved product line. The company, which has been in the industry for over 20 years, is known for its commitment to delivering top-notch grinding solutions to meet the needs of various industries.The newly introduced grinding discs come with several advanced features and are designed to provide superior performance and durability. These discs are suitable for a wide range of applications, including metal fabrication, construction, and automotive repair. With the introduction of these new products, Grinding Disc Company aims to further solidify its position as a trusted supplier of grinding solutions in the market.The new grinding discs boast a number of enhancements that set them apart from the competition. Firstly, they are manufactured using premium quality materials that have been rigorously tested to ensure excellent performance and longevity. The discs are also designed to deliver maximum precision and efficiency, allowing users to achieve high-quality results in their grinding operations.In addition, the new grinding discs feature an innovative design that minimizes heat generation and reduces the risk of overheating during prolonged use. This is a crucial benefit for users who rely on grinding discs for extended periods, as it helps to prevent damage to the workpiece and prolong the lifespan of the discs.Furthermore, the new grinding discs are equipped with a special coating that enhances their resistance to friction and wear. This ensures that the discs maintain their sharpness and cutting performance even when used in demanding applications. As a result, users can expect consistent and reliable performance from the discs, leading to improved productivity and cost savings.Grinding Disc Company is renowned for its dedication to customer satisfaction, and the introduction of the new product line is a testament to this commitment. The company understands the evolving needs of its customers and has invested significant resources in research and development to create grinding discs that are tailored to meet these requirements.“We are excited to introduce our new and improved grinding discs to the market,” said the spokesperson for Grinding Disc Company. “These discs have been meticulously engineered to deliver exceptional performance, and we believe that they will become a valuable asset for our customers. We are confident that the new product line will further cement our reputation as a trusted provider of high-quality grinding solutions.”As part of the launch, Grinding Disc Company has also announced special promotional offers to allow customers to experience the benefits of the new grinding discs. These offers include discounted pricing and bundled packages that provide added value to customers. With these promotions, the company hopes to encourage more users to try out the new products and witness the difference for themselves.The new product line is now available for purchase through Grinding Disc Company’s official distributors and authorized resellers. Customers can also reach out to the company directly to inquire about the availability of the new grinding discs and to learn more about their specifications and applications.Over the past two decades, Grinding Disc Company has built a strong reputation for delivering innovative grinding solutions that meet the highest standards of quality and performance. With the launch of the new product line, the company is poised to continue its legacy of excellence and remain at the forefront of the industry.For more information about Grinding Disc Company and its new and improved grinding discs, visit their official website or contact their customer service team.

How to Choose the Best Backing Pad for Your Projects

Backer Pad Company introduces newest innovative productBacker Pad Company is proud to introduce its latest innovative product designed to improve the efficiency and performance of various sanding and polishing applications. The company, known for its commitment to providing high-quality and reliable products, has developed the new backer pad to address the needs of professionals and DIY enthusiasts in the woodworking, automotive, and construction industries.The new backer pad is designed to provide exceptional support and durability for sanding and polishing discs, ensuring a smooth and consistent finish on a wide range of surfaces. Made from high-quality materials, the backer pad is engineered to withstand heavy-duty use while maintaining its effectiveness and performance over time. With its innovative design and superior construction, the backer pad has quickly become a must-have accessory for professionals and hobbyists alike."We are thrilled to introduce our newest backer pad to the market," said the spokesperson for Backer Pad Company. "We understand the demands and challenges that our customers face in their day-to-day work, which is why we are constantly striving to develop products that meet and exceed their expectations. The new backer pad is a testament to our commitment to innovation and quality, and we are confident that it will make a significant impact in various industries."Backer Pad Company has a long-standing reputation for delivering reliable and performance-driven products. The company's extensive experience and expertise in the industry have allowed it to establish a strong presence in the market, earning the trust and loyalty of customers around the world. With a focus on continuous improvement and innovation, Backer Pad Company remains dedicated to providing solutions that enhance the productivity and success of its customers.The new backer pad is now available for purchase through authorized distributors and retailers, allowing customers to experience its benefits firsthand. As part of the company's commitment to customer satisfaction, Backer Pad Company offers comprehensive support and assistance to help customers select the right backer pad for their specific applications. With its dedication to quality and performance, the company continues to set the standard for excellence in the industry.In addition to its new backer pad, Backer Pad Company offers a wide range of sanding and polishing accessories, including backing plates, sanding discs, and polishing pads. The company's extensive product line caters to the diverse needs of professionals and DIY enthusiasts, providing them with the tools they need to achieve outstanding results in their work. With a focus on customer satisfaction and product reliability, Backer Pad Company has earned a solid reputation as a leading provider of sanding and polishing solutions.As Backer Pad Company celebrates the release of its new backer pad, the company remains committed to its core values of innovation, quality, and customer service. With a dedicated team of professionals and a passion for excellence, the company looks forward to continuing its legacy of success and making a positive impact in the industry. Through its ongoing commitment to innovation and customer satisfaction, Backer Pad Company is poised to lead the way in providing cutting-edge solutions for sanding and polishing applications.For more information about Backer Pad Company and its range of products, please visit [company website] or contact [company email] for inquiries and assistance.

Durable and Reliable Bonded Grinding Wheels for Industrial Applications

Bonded Grinding Wheels, a leading manufacturer in the industry, has recently announced the release of their latest line of grinding wheels. With a focus on durability, efficiency, and precision, the company has continued to establish itself as a trusted provider of high-quality grinding solutions.As a leading manufacturer in the industry, Bonded Grinding Wheels has a proven track record of delivering innovative and reliable products to meet the diverse needs of their customers. With a comprehensive range of grinding wheels designed for a variety of applications, the company is dedicated to providing the best possible solutions for their clients.The company's commitment to quality and innovation is evident in their latest line of grinding wheels, which have been expertly designed and manufactured to deliver superior performance and long-lasting durability. The new line of grinding wheels features advanced bonding technology, ensuring maximum strength and stability during operation. This innovative approach to wheel design sets Bonded Grinding Wheels apart from its competitors, allowing the company to provide customers with cutting-edge solutions that deliver exceptional results.In addition to their focus on quality and performance, Bonded Grinding Wheels also prioritizes the safety of their products. With stringent quality control measures in place, the company ensures that each grinding wheel meets the highest standards for safety and reliability. This commitment to safety provides customers with peace of mind, knowing that they can trust Bonded Grinding Wheels to deliver products that prioritize their well-being.The company's dedication to customer satisfaction extends beyond product quality, as they also offer exceptional customer service and support. With a team of knowledgeable and experienced professionals, Bonded Grinding Wheels is equipped to provide expert guidance and assistance to customers, helping them find the right grinding solutions to meet their specific needs. Whether customers require custom-designed wheels or assistance with selecting the most suitable product for their application, the company's team is committed to delivering personalized service that exceeds expectations.Bonded Grinding Wheels' comprehensive range of grinding wheels caters to a wide range of industries and applications, including metalworking, automotive, aerospace, and more. The company's diverse product line reflects their commitment to meeting the unique needs of each customer, providing tailored solutions that deliver exceptional results. Whether customers require high-speed precision grinding wheels or heavy-duty abrasive wheels for tough materials, Bonded Grinding Wheels has them covered.As the company continues to innovate and expand its product offerings, Bonded Grinding Wheels remains dedicated to upholding the highest standards of quality, performance, and customer satisfaction. With a strong focus on research and development, the company is committed to staying ahead of industry trends and evolving customer needs, ensuring that they continue to provide innovative solutions that meet and exceed customer expectations.The release of their latest line of grinding wheels serves as a testament to Bonded Grinding Wheels' ongoing commitment to excellence and innovation. With a proven track record of delivering high-quality products and unparalleled customer service, the company is poised to maintain its position as a leader in the industry. Customers can confidently turn to Bonded Grinding Wheels for all their grinding needs, knowing that they will receive products that deliver outstanding performance, reliability, and safety.In conclusion, Bonded Grinding Wheels' latest line of grinding wheels represents the company's unwavering dedication to providing customers with the best possible solutions. With a focus on quality, performance, and customer satisfaction, the company continues to set the standard for excellence in the industry. Customers can trust Bonded Grinding Wheels to deliver innovative, reliable, and high-performance grinding solutions that meet their specific needs.

Polishing Concrete Floors: Tips for Cost, Equipment, and a Successful Finish

Concrete Floor Polishing for a High-End FinishGone are the days when concrete floors were simply a utilitarian option for warehouses and industrial spaces. Today, concrete floors are used not only for their durability but also as a stylish feature for modern homes and commercial buildings. With the process of concrete floor polishing, you can make a concrete floor look and feel like a high-end finished product.Concrete floor polishing involves grinding, honing, and polishing the surface of a concrete floor to achieve a smooth, glossy finish. The process is carried out using specialized equipment, including concrete polishing pads for floor buffer.If you are considering polishing your concrete floor, here are some things to consider before you start:1. The condition of your floor: The first thing to consider before polishing your concrete floor is its condition. The surface must be free of cracks, holes, and other damages.2. The level of smoothness you want: Concrete floor polishing can be done to different levels of smoothness depending on your preference. The smoother the floor, the more reflective it will be.3. The color of the floor: Polishing brings out the natural color of your concrete floor. You can choose to have a natural look or enhance the color using dyes or stains.4. The level of maintenance required: Polished concrete floors are easy to maintain, but you need to keep them clean and free of debris to retain their glossy finish.5. The cost: The cost of concrete floor polishing varies depending on the size of the floor, the level of polishing, and other factors.To achieve success with concrete floor polishing, you need the right equipment. This includes concrete polishing pads for floor buffer, which play a crucial role in the process. These pads come in different grits, which determine the level of polishing. The higher the grit, the smoother the finish.When it comes to concrete floor polishing, you should consider hiring a professional contractor. They have the expertise, experience, and equipment needed to achieve a high-quality finish. However, if you want to do it yourself, you can rent the equipment and purchase the necessary materials, including concrete polishing pads for floor buffer.In conclusion, concrete floor polishing is an excellent way to improve the look and feel of your space. It is a durable, low-maintenance option that can last for many years. Make sure you consider all the factors before embarking on the project, and use the right equipment, including concrete polishing pads for floor buffer.

Newly Developed Disc Grinding Wheel Offers Superior Performance and Durability

Title: Advanced Disc Grinding Wheel - Boosting Precision and Efficiency in Various IndustriesIntroduction:Marching ahead with its commitment to innovation and excellence, [Company Name] has introduced an advanced Disc Grinding Wheel that promises to revolutionize the grinding industry. With its cutting-edge technology and superior design, this state-of-the-art grinding wheel delivers unparalleled precision and efficiency, catering to the diverse needs of multiple industries. In this article, we will delve into the features and benefits of the Disc Grinding Wheel while shedding light on how it is set to transform the landscape of grinding.Precise and Reliable Performance:The Disc Grinding Wheel, developed by [Company Name], offers an exceptional level of precision and reliability in grinding applications. Designed with meticulous attention to detail, this product ensures the highest standards of accuracy, making it a top choice for professionals across industries such as automotive, aerospace, metalworking, and more. The grinding wheel's innovative composition allows for consistent and uniform contact with the workpiece, resulting in a smooth finish with minimal tolerances.Enhanced Efficiency and Productivity:One of the key advantages of the Disc Grinding Wheel is its ability to enhance efficiency and productivity in grinding operations. Thanks to its advanced abrasive technology, this grinding wheel provides exceptional material removal rates, reducing the time required for grinding tasks. This efficiency not only boosts productivity but also reduces operational costs, making it a cost-effective solution for companies aiming to optimize their manufacturing processes.Durability and Longevity:[Company Name]'s Disc Grinding Wheel is built to withstand rigorous usage, ensuring long-lasting performance. Constructed with high-quality abrasives and reinforced materials, this grinding wheel offers exceptional durability even when used in intense grinding environments. Its robust composition minimizes the risk of deformation or breakage, ensuring consistent performance over extended periods of use. This durability translates into reduced downtime for maintenance and replacement, further increasing efficiency and productivity.Safe and User-Friendly:Safety is paramount in any industrial setting. Recognizing this, [Company Name] has prioritized the safety aspects of the Disc Grinding Wheel. With carefully engineered designs, this product offers a high level of user-friendliness, reducing the risk of accidents or injuries. Its ergonomic grip and vibration reduction technology ensure optimum control and comfort during operation, minimizing operator fatigue and enhancing overall safety.Wide Range of Applications:The versatile nature of the Disc Grinding Wheel allows it to excel in various industrial sectors. From surface grinding and edge rounding to deburring and polishing, this grinding wheel can handle a wide range of applications with exceptional efficiency and precision. Its adaptability and versatility make it suitable for use across diverse industries such as automotive, aerospace, construction, and more, ensuring a cost-effective and reliable solution for grinding needs in different sectors.Sustainability and Environmental Responsibility:In line with [Company Name]'s commitment to sustainability and environmental responsibility, the Disc Grinding Wheel adheres to strict eco-friendly manufacturing practices. Constructed with fewer abrasive materials, this grinding wheel minimizes waste generation and reduces environmental impact. Additionally, its longevity and durability further contribute to reducing material consumption and waste generation, positioning it as an environmentally conscious choice.Conclusion:With [Company Name]'s introduction of the advanced Disc Grinding Wheel, the grinding industry is poised to experience a significant transformation. Combining precision, efficiency, durability, and sustainability, this state-of-the-art product is set to redefine the standards of grinding performance. By catering to a wide range of industries and applications, it serves as a reliable and cost-effective solution for professionals seeking unparalleled results. [Company Name] continues to innovate and push boundaries, enabling companies to achieve new heights of productivity and quality in their grinding operations.

Discover the Latest Innovative Diamond Pads for Enhanced Performance

Title: Revolutionary Diamond Pads Redefine Surface Polishing in the Construction IndustryIntroduction:In an industry that constantly seeks advancement to improve efficiency and quality, the introduction of Diamond Pads by a leading manufacturer is set to revolutionize the surface polishing process. This ground-breaking innovation brings together cutting-edge technology and industry expertise to deliver superior results and unparalleled durability. Let us delve deeper into the details of this extraordinary product that promises to reshape the construction industry.Paragraph 1:The construction industry has long relied on abrasive materials for surface polishing, which often results in subpar outcomes and rapid deterioration of equipment. However, with the recent release of Diamond Pads, this narrative is set to change. Unlike traditional abrasives, Diamond Pads utilize synthetic diamonds that guarantee exceptional performance, efficiency, and longevity, making them the preferred choice for contractors and construction professionals.Paragraph 2:The key feature that sets Diamond Pads apart is their use of synthetic diamonds, which are engineered to deliver unparalleled hardness and cutting ability. This enables the pads to effortlessly remove surface imperfections, such as scratches, stains, and unevenness, significantly reducing the need for manual labor and multiple polishing cycles. The enhanced cutting power of the synthetic diamonds ensures a smoother and more efficient polishing process, saving considerable time and resources for construction projects.Paragraph 3:Durability is a crucial factor in any construction product, and Diamond Pads excel in this aspect. The synthetic diamonds used in their manufacturing have exceptional wear resistance, enabling the pads to withstand prolonged usage without losing their cutting efficiency. This translates into significant cost savings, as contractors can now rely on a single set of Diamond Pads for multiple projects, eliminating the need for frequent replacements.Paragraph 4:Furthermore, the innovative design of Diamond Pads allows for versatile usage on a wide range of surfaces, including concrete, terrazzo, marble, and granite. This multi-purpose functionality makes them an all-in-one polishing solution for various construction applications, eliminating the necessity for multiple specialized tools. Not only does this streamline workflow, but it also reduces equipment costs, making Diamond Pads an economical choice for construction projects of any scale.Paragraph 5:Beyond their exceptional performance, Diamond Pads also prioritize sustainability. The synthetic diamonds used are ethically sourced and their manufacturing process adheres to environmentally conscious practices. This ensures that construction professionals can accomplish their projects while minimizing their environmental footprint, enhancing the industry's commitment to sustainable development.Paragraph 6:To guarantee customer satisfaction, the manufacturer provides comprehensive support services, including training programs and expert guidance on the proper usage and maintenance of Diamond Pads. This ensures that contractors optimize the product's capabilities, maintain its longevity, and achieve the best possible results on every project.Closing paragraph:In the fast-paced construction industry, Diamond Pads represent a game-changing innovation that promises to redefine surface polishing. With their exceptional cutting power, durability, versatility, and sustainability, they offer a cost-effective and efficient solution for contractors seeking high-quality results. As the industry embraces this groundbreaking technology, construction projects around the world can expect to experience significant improvements in surface polishing processes for years to come.