Versatile Grinding Wheels for Industrial Metal Work and Deburring Applications

By:Admin

Grinding Wheels and Tooling for Industrial Applications

Grinding wheels are essential tools for metalworking, deburring, and machine-mounted works. They come in various shapes and sizes and are known to be one of the most versatile abrasive tools available in the market. They are made of abrasive grains, bonding materials, and fillers, and can be used for a wide range of tasks. In this article, we will discuss the different types of grinding wheels and tooling for industrial applications.

Bonded Grinding Wheels

Bonded grinding wheels are the most commonly used type of grinding wheel. They are made of a composite material that consists of abrasive grains held together by a bonding material. The abrasive grains are usually made of aluminum oxide, silicon carbide, or diamond, depending on the type of material being ground and the desired finish. The bonding material can be resin, metal, or vitrified.

Resin-bonded wheels are commonly used for precision grinding, surface grinding, and tool and cutter grinding. They are versatile and affordable, making them suitable for most applications. Metal-bonded wheels are used for grinding harder materials, such as high-speed steel and carbide. They are also used for rough grinding and form grinding. Vitrified-bonded wheels are used for precision grinding and sharpening of carbide tools.

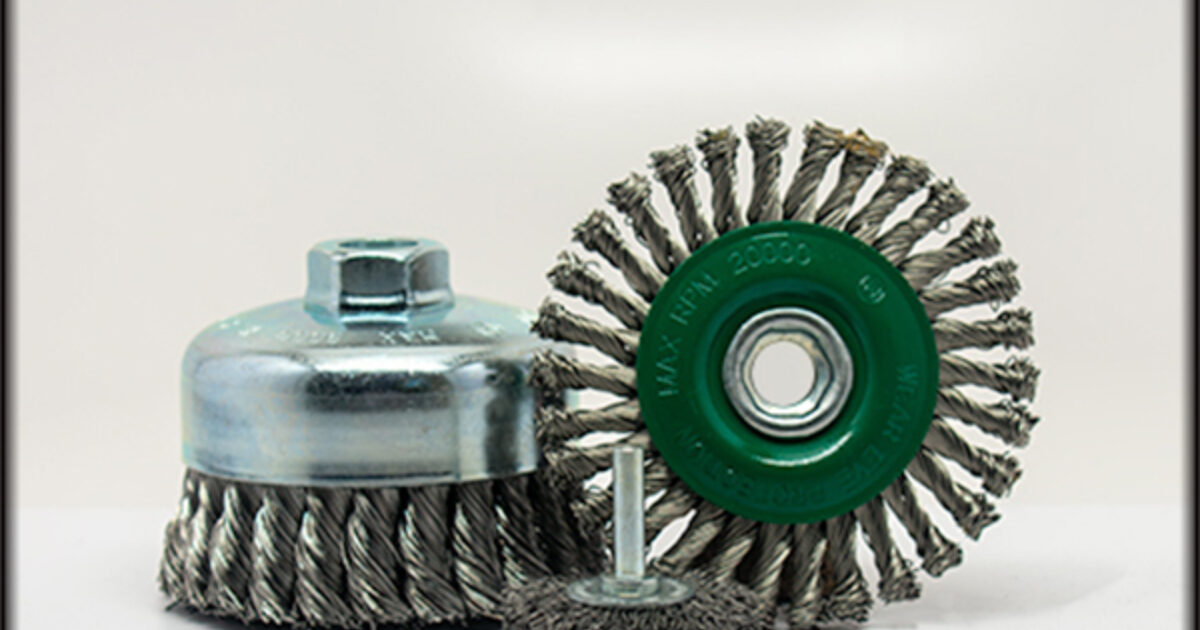

Wire Brushes

Wire brushes are another type of abrasive tool that is used for cleaning, deburring, and finishing metal surfaces. They are made of metal wire bristles that are mounted on a rotating shaft. The wire bristles can be made of different materials, including steel, brass, and stainless steel. Wire brushes are used for removing rust, paint, and other surface contaminants from metal surfaces. They are also used for cleaning welds and deburring edges.

Bench Mounted Applications

Bench-mounted grinding wheels are used for precision grinding, sharpening, and polishing of metal parts. They are mounted on a bench or pedestal and can be used for a wide range of tasks, such as grinding, deburring, and sanding. Bench-mounted wheels are available in various sizes and materials, depending on the application.

Surface Grinding Wheels

Surface grinding wheels are used for precision grinding of flat surfaces. They are typically used on a reciprocating table, where the workpiece is moved back and forth against the grinding wheel. Surface grinding wheels are available in different sizes and materials, depending on the type of material being ground and the desired finish.

Carbide Burrs

Carbide burrs are used for shaping, deburring, and finishing metal surfaces. They are made of carbide, a hard and brittle material that is ideal for grinding and cutting. Carbide burrs are available in various shapes and sizes, depending on the application. They can be used on a variety of materials, including steel, aluminum, and cast iron.

In conclusion, grinding wheels and tooling for industrial applications are essential tools for metalworking, deburring, and machine-mounted works. Bonded grinding wheels, wire brushes, bench-mounted applications, surface grinding wheels, and carbide burrs are just some of the available options. When choosing a grinding wheel or tool, it is important to consider the type of material being ground, the desired finish, and the application.

Company News & Blog

High-Quality Polishing Pads for Angle Grinders - Perfect for Marble, Granite, Concrete, and Glass - Global Shipping Available

Polishing Pads for Angle Grinder: The Ultimate Guide for Polishing Various MaterialsAre you looking for a versatile and efficient way to polish materials such as marble, granite, concrete, or even glass? Look no further! In this comprehensive guide, we will explore the world of polishing pads for angle grinders, providing valuable insights and tips on how to achieve a flawless finish. Whether you are a professional stone fabricator or simply an avid DIY enthusiast, understanding the different types of grinder pads for polishing will undoubtedly take your polishing game to the next level.Before diving into the details of grinder pads for polishing, let's take a moment to appreciate the significance of the angle grinder itself. Owing to its compact size and high rotational speed, the angle grinder has become a popular choice among professionals and amateurs alike. Its versatile nature allows it to perform a plethora of tasks, including cutting, grinding, and, of course, polishing. Pairing this mighty tool with the right polishing pad can transform it into a powerful weapon for achieving spectacular results.Now, let's shift our focus to the star of our discussion – polishing pads. Polishing pads are essential tools used to refine and bring out the natural beauty of various materials. These pads consist of a base material with an abrasive surface designed to work effectively on different surfaces. There are several factors to consider when selecting the appropriate pad for a specific material, such as hardness, grit size, and pad composition.When it comes to hardness, it is crucial to match the pad to the material you are working on. For instance, softer pads are recommended for delicate surfaces like glass, while harder ones are more suitable for granite or concrete. This careful selection ensures optimal results without causing any damage to the material.Another crucial aspect to consider is the grit size of the pad. Grit size refers to the size of the abrasive particles embedded in the pad. The general rule of thumb is to start with larger grit sizes and progressively move to finer ones for a flawless finish. Coarser grit sizes, such as 50 or 100, are ideal for initial material removal or leveling uneven surfaces, while finer grit sizes like 400 or 800 are perfect for achieving a mirror-like shine.In terms of pad composition, there are several options available on the market. Diamond polishing pads, for example, are widely recognized for their durability and effectiveness. These pads use diamond particles bonded to the pad surface to perform efficient material removal and polishing. Their high quality ensures a longer lifespan and superior performance compared to traditional pads.Additionally, resin polishing pads are gaining popularity due to their versatility and user-friendliness. These pads utilize a combination of resin and diamond particles to provide excellent polishing results. Their flexible nature allows them to adapt to irregular surfaces, making them ideal for rounded edges or curved areas.One noteworthy feature of many polishing pads is the presence of water holes. These holes play a crucial role in cooling down the pad during the polishing process, reducing the risk of overheating and ensuring smoother operations. It is advisable to select pads with a suitable number and arrangement of water holes, depending on the intensity and duration of the polishing job at hand.Now that we have covered the essentials of polishing pads for angle grinders, it's time to highlight the significance of international shipping. If you are a professional stone fabricator or a passionate DIYer, sourcing high-quality grinder pads for polishing locally might not always be possible or financially feasible. Nevertheless, many reputable online platforms offer international shipping services, enabling you to access a wide range of polishing pads at competitive prices, irrespective of your geographic location.In conclusion, grinder pads for polishing are indispensable tools for achieving exceptional results when working with materials like marble, granite, concrete, and glass. By understanding the importance of hardness, grit size, and pad composition, you can select the perfect pad for your specific needs. Furthermore, considering the advantages of online marketplaces that offer international shipping, you can effortlessly access high-quality and affordable polishing pads from anywhere in the world. So, gear up your angle grinder, grab the appropriate polishing pads, and get ready to transform ordinary surfaces into stunning masterpieces!

High-Quality Hybrid Floor Polishing Pad, Concrete Floor Pad, and Diamond Tools at Affordable Prices

: The Revolution in Polishing TechniquesPolishing floors was once a highly labor-intensive task that requires time, effort, and a plethora of technical skills. Plus, the traditional methods used to polish floors often lead to pesky issues, such as uneven surfaces, scratches, and long drying periods. Luckily, thanks to the inception of diamond floor pads, this laborious task can be accomplished with greater efficiency and in less time. So, what exactly are diamond floor pads?Diamond floor pads are a revolutionary new tool used in the process of polishing concrete, marble, and granite surfaces. These pads are made from diamond particles, which are skillfully combined with advanced bonding materials to form a highly effective and durable surface polishing tool. Additionally, the diamond floor pad has numerous benefits over earlier polishing techniques.One of the significant benefits of diamond floor pads is that they can be used for both dry and wet polishing. Unlike traditional methods that could only be executed after the surface had already dried, these new pads allow for an enhanced polishing experience. Dry polishing was previously used to tackle surface imperfections caused by uneven wear and tear. The diamond floor pads have now changed that scenario and polish the floor to a smooth, glossy finish.Another major advantage of diamond floor pads is their ability to create a more even finish across the entire floor's surface area. The pads are made with diamond particles of varying diameters that allow the operator to adjust the levels depending on the surface's texture. Additionally, diamond floor pads can be used to remove dirt, oil, and grime from the surface when used with the appropriate detergent.Diamond floor pads are also a more cost-effective option than traditional polishing surfaces. Since traditional polishing tools require a significant amount of equipment, such as special chemicals, machines, and additional labor, the overall expenses of the process can be quite expensive. Diamond floor pads make the process more cost-effective as it does not require extensive equipment, and it can be performed without rigorous training.The surfaces that diamond floor pads can polish are also diverse. These pads are effective in polishing various surfaces, including concrete, granite, marble, tiles, and porcelain. The advanced design and construction of diamond floor pads allow them to handle rough, bumpy surfaces and achieve the desired smooth surface finish with ease. It can be used for polishing indoors and outdoors, giving your floors a beautiful glossy appeal.Hybrid floor polishing pad is an extension of diamond floor pads. The hybrid floor pads typically have a grit range of 400-3000 and have diamond resin or metal segments embedded in them. These pads can quickly do the job of both metal and resin-bonded tools in one go, which is why there are becoming increasingly popular in the floor polishing world.The transition tools are used in the preparation phase, from grinding to polishing. The angle of the transition tools is precisely adjusted to avoid damaging the new surface while preparing it for the next stage. Proper use of the transition tool is essential to achieve the perfect floor finish.In conclusion, diamond floor pads have revolutionized floor polishing techniques. They're cost-effective, efficient, and versatile and can polish various surfaces to a beautiful gloss finish. The hybrid floor polishing pad and transition tools are beneficial in the overall process of polishing floors. By employing these innovative tools, we can finally say goodbye to the laborious, time-consuming, and costly process of polishing floors. Get your diamond floor pad today and experience the perfect floor finish.

Effortlessly Tackle Wood Floor Sanding with Electric Sanding Machines

Wood Floor Sanding Made Easy with Electric MachinesWood floor sanding is a crucial step in maintaining and restoring the beauty of your wooden floors. Whether you are refinishing old flooring or preparing new wood floors for a finish, sanding plays a vital role in achieving a smooth and flawless surface. While sanding can be done manually, the process becomes much more efficient and time-saving with the help of electrically driven sanding machines.DoItYourself.com, a leading online resource for DIY projects and home improvement, recognizes the significance of using electric sanding machines in large-scale wood floor sanding projects. With their power and versatility, these machines have revolutionized the way professionals and homeowners tackle flooring projects.One such highly regarded machine in the industry is the Wood Floor Sanding Edging Machine, produced by a renowned company (brand name removed). This powerful machine has earned a reputation for its exceptional performance and user-friendly features. Equipped with state-of-the-art technology, it enables efficient sanding along the edges of wood floors, reaching corners and tight spaces with ease.The Wood Floor Sanding Edging Machine boasts a robust motor that delivers high-speed sanding, effectively removing old finishes, stains, and scratches. Its ergonomic design ensures comfortable handling, reducing operator fatigue during extended sanding sessions. The machine is also equipped with a dust extraction system, keeping the work area clean and minimizing the risk of respiratory issues caused by wood dust.One of the standout features of this machine is its adjustable sanding depth, allowing users to achieve precise sanding results according to their unique requirements. The maneuverability of the Wood Floor Sanding Edging Machine is another notable advantage, as it effortlessly glides over the surface, creating a uniform finish without leaving any swirl marks or gouges.A notable advantage of using electric sanding machines for wood floor sanding is the significant reduction in project time. Compared to manual sanding, which requires extensive physical effort and a multitude of sanding pads, electric machines can accomplish the task in a fraction of the time. This makes them ideal for both professional contractors with tight deadlines and homeowners looking to complete their DIY projects efficiently.Furthermore, electric sanding machines ensure consistent results across the entire wood floor surface. The design of these machines allows for uniform pressure distribution, minimizing the risk of uneven sanding or overworking certain areas. This guarantees a smooth and level surface, ready for the application of finishes or sealants.In conclusion, electrically driven sanding machines have become an essential tool for wood floor sanding projects. Their power, efficiency, and ease of use make them indispensable for professionals and DIY enthusiasts alike. The Wood Floor Sanding Edging Machine, provided by the reputable company (brand name removed), exemplifies the cutting-edge technology and user-centric design that has propelled sanding machines to new heights. So, whether you are embarking on a large-scale flooring project or simply restoring a single room, utilizing electric sanding machines will undoubtedly streamline the process and leave your wood floors looking stunning.

Suppliers of Abrasives and Welding Equipment: Reviews and Product Info

Title: Enhancing Metal Finishing Processes with High-Quality AbrasivesIntroduction (approx. 100 words):When it comes to achieving stellar results in metal finishing processes, using top-notch abrasives is crucial. From sandpapers and grinding wheels to polishing compounds, these abrasive materials play a significant role in refining metal surfaces, removing imperfections, and ensuring a smooth end result. In this blog, we will delve into the world of abrasives, shedding light on the importance of choosing reputable suppliers and the benefits of utilizing high-quality metal abrasives. Join us as we explore the key factors to consider when selecting abrasives and learn how they can elevate your metal finishing processes to new heights.1. Understanding the Role of Abrasives in Metal Finishing (approx. 200 words):Metal finishing encompasses a wide range of processes, such as abrasive blasting, grinding, sanding, and polishing. These techniques aim to improve the appearance, functionality, and longevity of metal surfaces. At the core of each process lies the abrasive materials, which streamline the entire metal finishing journey.Abrasives serve as the key agents of change in metal finishing by removing unwanted material layers, leveling imperfections, and ensuring a uniform surface. They can be categorized based on their composition, size, and intended purpose. From natural abrasive minerals like garnet and diamond to synthetic options like aluminum oxide and silicon carbide, suppliers offer an extensive range of metal abrasives suitable for various applications.2. The Importance of Reliable Abrasive Suppliers (approx. 250 words):When selecting a supplier for your metal abrasives, it is crucial to prioritize reliability, quality, and customer service. Choosing the wrong supplier can lead to subpar products, delays, and overall dissatisfaction. Therefore, thorough research and consideration are necessary to make an informed decision.Reliable suppliers boast impeccable track records and positive customer reviews. These indicators of customer satisfaction are a testament to the supplier's commitment to quality. By collaborating with established suppliers, you gain access to a wide range of high-quality metal abrasives that will enhance your metal finishing processes.Additionally, reputable suppliers often provide ample product and service information, empowering customers to make well-informed purchasing decisions. Detailed profiles of suppliers allow you to understand their expertise, experience, and capabilities, enabling you to choose a partner that aligns with your specific needs.3. Benefits of High-Quality Metal Abrasives (approx. 250 words):Investing in high-quality metal abrasives can transform your metal finishing processes and yield remarkable results. Here are some key benefits of using premium abrasives:- Enhanced Efficiency: High-quality abrasives exhibit superior cutting, grinding, and polishing capabilities, allowing you to accomplish tasks more efficiently, saving both time and resources.- Superior Surface Finish: Premium abrasives enable you to achieve impeccable surface finishes by removing imperfections, scratches, and roughness efficiently, resulting in aesthetically pleasing and durable metal surfaces.- Extended Abrasive Lifespan: Top-notch metal abrasives often boast increased durability and longevity, reducing the need for frequent replacements and leading to cost savings in the long run.- Consistency and Precision: Reliable suppliers ensure consistent quality across their abrasive products, promoting precise performance and predictable outcomes in your metal finishing processes.Conclusion (approx. 150 words):Choosing the right supplier for your metal abrasive needs is paramount to achieve exceptional results in metal finishing processes. By selecting reputable suppliers and investing in high-quality metal abrasives, you can enhance efficiency, improve surface finishes, extend abrasives' lifespan, and achieve consistent and precise outcomes. Take advantage of the wide array of metal abrasives available in the market and revolutionize your metal finishing processes today.

Secure Your Home with a Heavy-Duty Copper and Steel Safety Door

Metal Copper Bonds: The Strength of Steel and the Elegance of CopperWhen it comes to home security, one of the most important considerations is the entry door. A strong and durable door not only provides protection from intruders, but also adds to the aesthetic appeal of your home. If you are looking for a door that combines strength and elegance, the Home Entry Heavy-Duty Steel Safety Metal Screen Stop Security Door is the perfect choice for you. With its unique combination of steel and copper, this door offers both security and style.The door is made of heavy-duty steel which provides unparalleled strength and durability. The steel construction ensures that the door cannot be easily broken into, making it an ideal choice for those concerned about home security. The steel material also makes the door highly resistant to weather, ensuring that it will withstand harsh conditions for years to come.While steel offers superior strength, sometimes it lacks in aesthetic appeal. That is where the copper element comes in. Copper is one of the oldest building materials in the world, and has been used for thousands of years because of its beauty and durability. The copper gives the door a classic and elegant look, which can add to the overall aesthetic appeal of your home. The copper element also adds a layer of protection to the door. Copper has natural anti-bacterial and anti-microbial properties which help to prevent the growth of bacteria and other harmful microorganisms on the surface of the door.The Home Entry Heavy-Duty Steel Safety Metal Screen Stop Security Door is also equipped with a metal screen which further enhances the security features of the door. The screen is made of high-quality steel which is designed to prevent intruders from entering your home. The screen also provides an added layer of protection against insects and pests, without compromising the flow of fresh air into your home.Another important feature of the door is the stop mechanism. The door is designed with a built-in stop which prevents it from opening too far and causing damage to the hinges. This will help to keep the door in good condition for years to come, and prevent the need for costly repairs in the future.Overall, the Home Entry Heavy-Duty Steel Safety Metal Screen Stop Security Door is an excellent choice for those who want to increase the security of their home. The combination of steel and copper makes it a highly durable and attractive option, while the metal screen and stop mechanism provide additional layers of protection. Whether you are looking to enhance the aesthetic appeal of your home, or simply want to feel more secure, this door is an excellent investment. So why not add some metal copper bonds to your home today?

Versatile Diamond Polishing Pads for Granite, Marble, Stone, and More

Diamond Resin Dry Polishing Pads: Perfecting the Art of Stone PolishingDiamond polishing pads have become an indispensable tool in the field of stone polishing. With their ability to enhance the appearance of various types of surfaces such as granite, marble, engineered and natural stone, concrete, terrazzo, countertops, and floors, these pads have revolutionized the way we finish and beautify these materials. Among the many options available, Diamond Resin Dry Polishing Pads stand out as one of the best choices for achieving impeccable results. In this blog, we will explore the features, benefits, and applications of these remarkable pads that have taken the industry by storm.The first thing that sets Diamond Resin Dry Polishing Pads apart is their composition. Crafted using the finest quality of diamonds and resin, these pads are designed to deliver exceptional polishing performance. The diamonds embedded in the resin matrix provide the necessary cutting power, while the resin acts as a bonding agent, ensuring durability and longevity.One of the primary advantages of using Diamond Resin Dry Polishing Pads is their versatility. They can be used on a variety of surfaces, ranging from granite to marble, engineered and natural stone, concrete, terrazzo, countertops, and floors. This gives contractors and polishing professionals the flexibility to work on different projects without the need for multiple sets of pads. Whether you are polishing a kitchen countertop or a luxurious marble floor, Diamond Resin Dry Polishing Pads are your go-to solution.Another remarkable feature of these pads is their ability to perform effectively in dry polishing applications. Traditionally, wet polishing has been the preferred method due to its cooling effect, dust suppression, and easier debris removal. However, dry polishing offers its own set of advantages, such as convenience, versatility, and cost-effectiveness. Diamond Resin Dry Polishing Pads excel in this area, providing a superior dry polishing experience by delivering exceptional results without the need for water or slurry.Additionally, Diamond Resin Dry Polishing Pads offer enhanced flexibility and adaptability. Their design allows them to conform to the shape and contours of the surface being polished, ensuring even distribution of pressure and an immaculate finish. This makes them an ideal choice for intricate designs and curved surfaces, where achieving a perfect polish can be quite challenging.When it comes to achieving a high-gloss shine, Diamond Resin Dry Polishing Pads are second to none. The combination of diamond and resin creates a synergy that not only removes scratches and imperfections but also imparts a lustrous and reflective finish to the surface. This property is particularly significant in applications where aesthetics play a crucial role, such as luxury hotels, high-end residential properties, and commercial spaces.In terms of performance, Diamond Resin Dry Polishing Pads offer exceptional efficiency and endurance. The diamonds embedded in the pads ensure consistent cutting power, allowing for faster material removal and uniform polishing. This, coupled with their exceptional durability, makes them a cost-effective investment that can withstand rigorous use and produce superior results over an extended period.In conclusion, Diamond Resin Dry Polishing Pads have become a game-changer in the world of stone polishing. Their ability to polish various surfaces, adapt to different shapes, and deliver impeccable results without the need for water or slurry make them an essential tool for contractors and polishing professionals. Whether you are looking to enhance the beauty of your granite countertop, transform your marble floors, or revamp your terrazzo surfaces, Diamond Resin Dry Polishing Pads are your trusted companion. Invest in these pads and elevate your stone polishing projects to new heights of perfection.

Supplier of Wet Polishing Pad - Weihai Chengxun Import & Export Co., Ltd. offers a wide range of stone products

Weihai Chengxun Import & Export Co., Ltd. – Your Top Partner for Premium Quality Polishing PadsIf you are in the market for the highest quality polishing pads, then look no further than Weihai Chengxun Import & Export Co., Ltd. For years now, we have been providing customers from all over the world with exceptional polishing pads that deliver superior results. Our products have become recognized globally as the best in class, as we utilize only the finest materials to manufacture them.At Weihai Chengxun Import & Export Co., Ltd., we understand the importance of high-quality pads that are able to withstand and adapt to any surface, while delivering an unmatched performance. It is for this reason that we have placed customer satisfaction at the core of our operations, and this has made us a leading supplier of wet polishing pads in the market.Our premium quality polishing pads are manufactured with leading-edge production technology. This ensures that our products remain innovative, durable, and able to provide superior polishing results. We are committed to quality, and this shows in the way our products have been able to withstand the test of time.Our wet polishing pads are a favorite among many customers around the world. They are engineered for use with a wet polishing machine and are ideal for granite or marble, as they yield a glossy finish. Additionally, our wet polishing pads are available in different configurations and sizes, so you can choose the one that best suits your needs.At Weihai Chengxun Import & Export Co., Ltd., we believe that our customers deserve the best quality products, and we are dedicated to providing that to them. Our products are designed to deliver unmatched performance and quality, making them a valuable investment for your business. Our wet polishing pads have been tested and proven to withstand the toughest polishing jobs and conditions.Moreover, Weihai Chengxun Import & Export Co., Ltd. is home to some of the most experienced and skilled professionals in the field of polishing pads. Our team is knowledgeable, dedicated, and committed to customer satisfaction. They are always on standby to answer any questions or concerns that our customers may have regarding our products. We also provide regular training to our team to ensure that they stay current with industry trends and standards.In addition to wet polishing pads, our product line also includes dry polishing pads, diamond saw blades, grinding wheels, concrete cutting tools, and much more. We also offer customization services, tailoring our products to the unique needs of our esteemed customers.At Weihai Chengxun Import & Export Co., Ltd., we understand that the success of our clients' businesses is vital to our own success. Therefore, we have made it our mission to provide our customers with value-added services that set us apart from other polishing pad suppliers.In conclusion, if you are in the market for top-quality polishing pads that offer superior performance, then look no further than Weihai Chengxun Import & Export Co., Ltd. Our products have become renowned globally for their quality and consistent delivery of superior results. Call us today and take your polishing experience to the next level!

High-Quality and Affordable Diamond Polishing Pads for Various Applications

- Importance of Diamond Polishing Pads for Stone RestorationStone restoration is a process that is becoming increasingly popular as people are realizing the benefits of restoring old and damaged stone surfaces. However, the process of stone restoration requires the use of specialized tools and equipment, including diamond polishing pads. These pads are specifically designed to restore stone surfaces to their original beauty and shine. In this blog post, we will discuss the importance of diamond polishing pads in stone restoration.Diamond polishing pads are designed to work with a wide variety of stone surfaces, including marble, granite, and other natural stone materials. They come in different sizes and grits to suit different types of stone surfaces and specific restoration needs. These pads are typically made of diamond-impregnated resin or metal-bonded diamond, which allows them to grind away the surface imperfections and smooth out the stone.The use of diamond polishing pads is an essential part of the stone restoration process. They are used to remove surface scratches, stains, and blemishes, as well as to bring out the natural beauty and shine of the stone. Diamond pads are also used to flatten uneven surfaces, smooth out rough edges, and to achieve a high-gloss finish.When selecting a diamond polishing pad for a stone restoration project, it is important to consider the type of stone surface being restored and the level of damage. The pads come in different grits, ranging from coarse to fine, and each grit is designed for a specific purpose. Coarse grit pads are used for heavy grinding and removing deep scratches and stains. Medium grit pads are used for smoothing out surface imperfections, and fine grit pads are used for achieving a high-gloss finish.In addition to using the appropriate grit, it is important to use the proper technique when using diamond polishing pads. Proper technique involves using a consistent amount of pressure and controlling the speed of the rotary tool. It is also important to use water or a special lubricating fluid to cool the pad and prevent it from overheating.In conclusion, the use of diamond polishing pads is crucial for restoring stone surfaces to their original beauty and shine. With the proper selection of grit, technique, and equipment, diamond pads can be used to remove scratches, stains, and imperfections, as well as to achieve a high-gloss finish. If you are considering a stone restoration project, be sure to work with a professional who understands the importance of using diamond polishing pads for the best results.

Advanced Holders for Cutting Tools, Diamond Tools, CBN Tools, and Laser Optics

Diamond Tool Holders: Revolutionizing the Industrial Cutting ProcessIn the realm of cutting tools, there is an ever-growing demand for increased efficiency and precision. Industries across the board, from automotive to aerospace, are constantly seeking innovative solutions to optimize their manufacturing processes. This pursuit has led to the development of diamond tool holders, a game-changing technology that has revolutionized industrial cutting.Diamond tool holders are essential components in cutting machinery, serving as the interface between the machine and the cutting tool. They are meticulously designed to provide stability, accuracy, and durability. The incorporation of diamonds in the tool holder material adds an extra layer of robustness, making it much more resistant to wear and tear compared to traditional tool holders.One of the key advantages of diamond tool holders is their exceptional hardness. Diamonds are known to be one of the hardest substances on Earth, surpassing all other materials commonly used in tool holders. This unique property allows diamond tool holders to withstand the extreme forces and temperatures experienced during cutting operations, resulting in a longer tool life. As a result, manufacturers can significantly reduce downtime and tool changeovers, leading to enhanced productivity and cost savings.Another noteworthy characteristic of diamond tool holders is their superior thermal conductivity. Heat generation is an inherent challenge in cutting processes, as excessive heat can negatively impact the tool's performance and lead to premature failure. However, diamond tool holders effectively dissipate heat due to their excellent thermal conductivity, ensuring the tool remains at an optimal temperature. This feature is particularly beneficial in high-speed cutting applications where heat buildup is a common concern.Furthermore, diamond tool holders minimize vibrations during machining operations. Vibrations can have a detrimental effect on the quality and precision of the final product. The inherent stiffness and rigidity of diamond give these tool holders remarkable dampening capabilities, reducing vibrations to negligible levels. By mitigating vibrations, diamond tool holders contribute to smoother cutting actions and improved surface finishes, meeting the stringent quality requirements of various industries.Diamond tool holders also excel in their ability to maintain dimensional accuracy. Precision is a critical factor in industries that demand tight tolerance in their manufacturing processes. Diamond's exceptional hardness and wear resistance ensure that the tool holder maintains its shape and size over extended periods of use. This consistent dimensional stability translates to consistent, high-quality products and eliminates the need for frequent adjustments or replacements.Moreover, the introduction of diamond tool holders has significantly expanded the scope of cutting tool applications. Diamond tool holders are compatible with a wide range of cutting tools, including both diamond and CBN (cubic boron nitride) tools. This versatility allows users to select the most suitable cutting tool for their specific application, optimizing performance and achieving desired outcomes. Industries such as automotive, aerospace, and medical device manufacturing have greatly benefited from this increased flexibility in tooling options.In conclusion, diamond tool holders have transformed the industrial cutting landscape. Their exceptional hardness, thermal conductivity, and dampening capabilities make them a superior choice for precise, efficient, and reliable cutting operations. By choosing diamond tool holders, manufacturers can improve productivity, achieve consistent and high-quality results, reduce downtime, and ultimately save costs. As the cutting tool industry continues to evolve, diamond tool holders remain at the forefront of innovation, empowering industries to push the boundaries of what is possible in the realm of cutting technology.

On-Site Dry Polishing Pads for Stone and Concrete Surfaces: An Effective Solution for Marble, Granite, and More

Dry diamond polishing pads are a versatile and cost-effective solution for on-site dry polishing of marble, granite, and other natural stones. These pads are perfect for the DIY enthusiast, contractor, or anyone looking for an inexpensive and efficient way to polish stone surfaces.Dry diamond polishing pads are designed for use on the most common types of stone, including granite, marble, and concrete. They can be used on walls, floors, countertops, and other surfaces, making them a great option for a variety of residential and commercial applications.The benefits of using dry diamond polishing pads for granite and other stone surfaces are numerous. First, they offer excellent performance at a low cost. Because they are designed for dry use, there is no need to pay for costly water and electricity. Additionally, since dry diamond polishing pads are lightweight and easy to use, they do not require the use of heavy machinery or specialized equipment.Another benefit of using dry diamond polishing pads is their versatility. They come in a variety of different grits, which makes it easy to achieve the desired level of finish. From rough grinding to fine polishing, there is a pad available to suit every need.Finally, dry diamond polishing pads are a great choice for environmentally-conscious consumers. Since they are designed for use without water, there is no need to worry about water runoff or other environmental concerns.In conclusion, if you are looking for an efficient, cost-effective, and eco-friendly way to polish your stone surfaces, look no further than dry diamond polishing pads. With their versatility, affordability, and ease of use, these pads are the perfect solution for anyone looking to achieve a beautiful and professional-looking finish on their granite or other natural stone surfaces.